Specialty Series

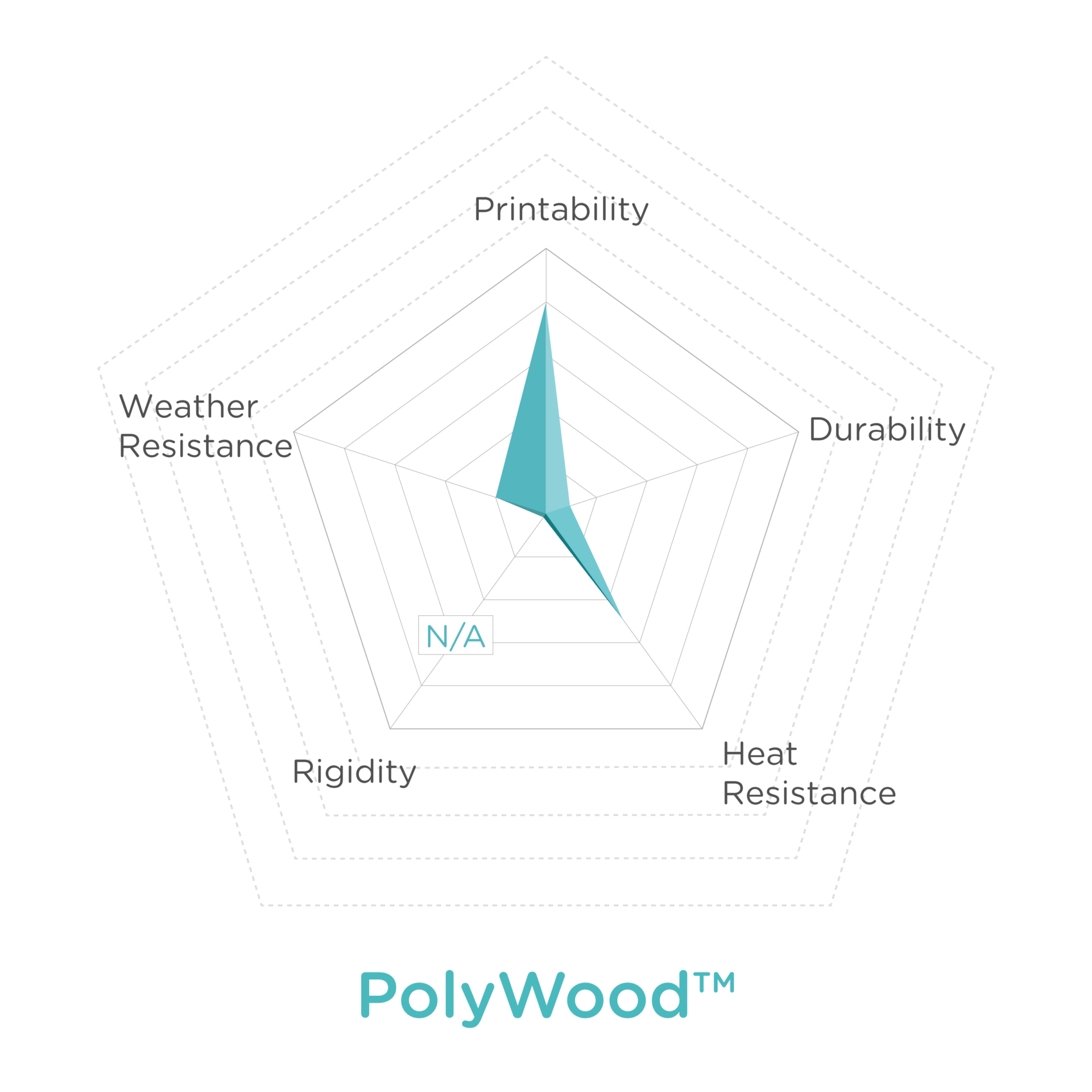

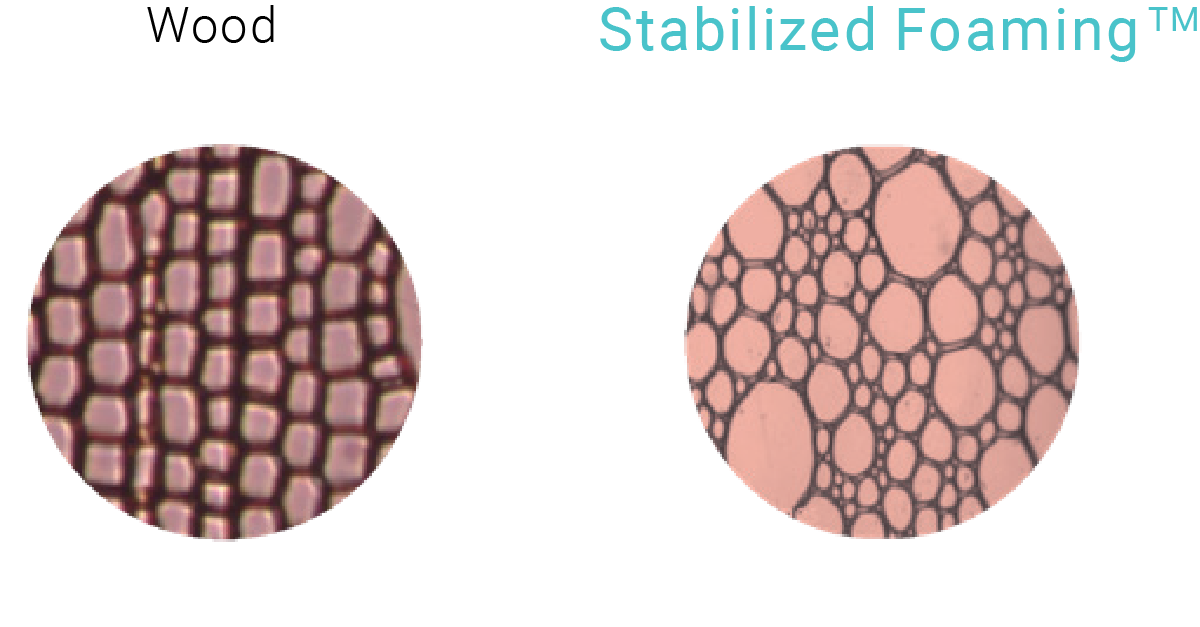

PolyWood™ is a wood mimic filament containing no actual wood powder, which removes all risks of nozzle clogs. PolyWood™ is made entirely with PLA using Polymaker’s Stabilized Foaming™ technology which reduces the density of the PLA by 30%. The printed models take on a unique matte surface finish which when printed at high resolution can completely mask the layers.

What makes PolyWood™ unique?

PolyWood™ is a wood mimic filament without actual wood powder, which removes all risks of nozzle clogs. PolyWood™ is made entirely with PLA using a special foaming technology. It exhibits similar density and appearance as wood.

What makes PolyWood™ unique?

PolyWood™ is a wood mimic filament without actual wood powder, which removes all risks of nozzle clogs. PolyWood™ is made entirely with PLA using a special foaming technology. It exhibits similar density and appearance as wood.

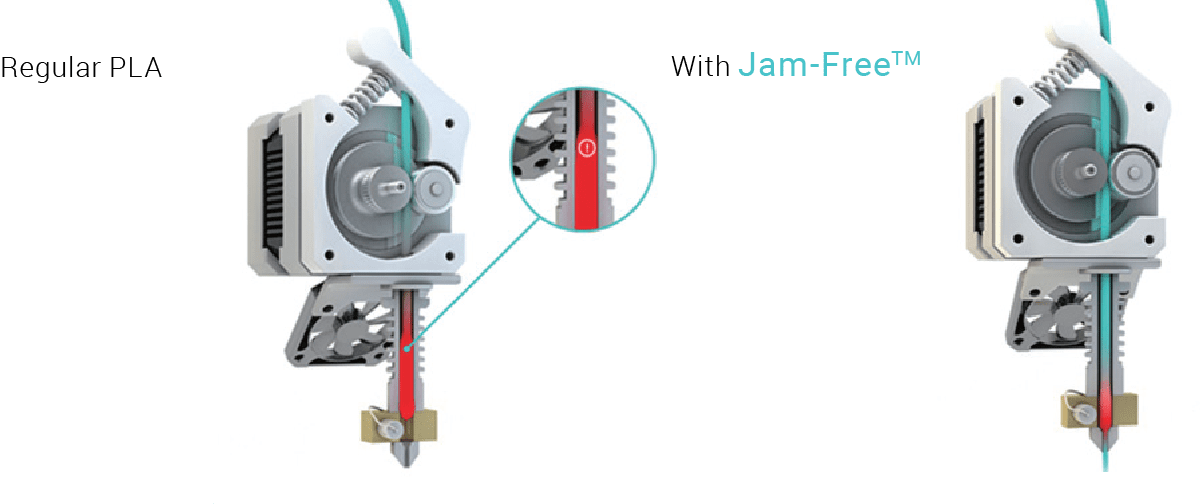

Jam-Free™ technology

Stabilized Foaming technology

* Please note that availability of certain SKUs may vary by location and not all products may be accessible at every reseller. We recommend contacting your local reseller for specific product availability in your region. You can also contact our regional sales team for more details.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.

Please fill in the form below or if you have other questions are not included in the form, please contact us through [email protected]. We will get back to you soon.