PLA

PETG

ABS/ASA

PC

PA(Nylon)

TPU

PVB

Support

Comparison

PolySonic™ PLA

High Speed PLA

Accurate & Repeatable

Accurate & Repeatable

PolySonic™ PLA Pro

High Speed PLA

Fast & Tough

Fast & Tough

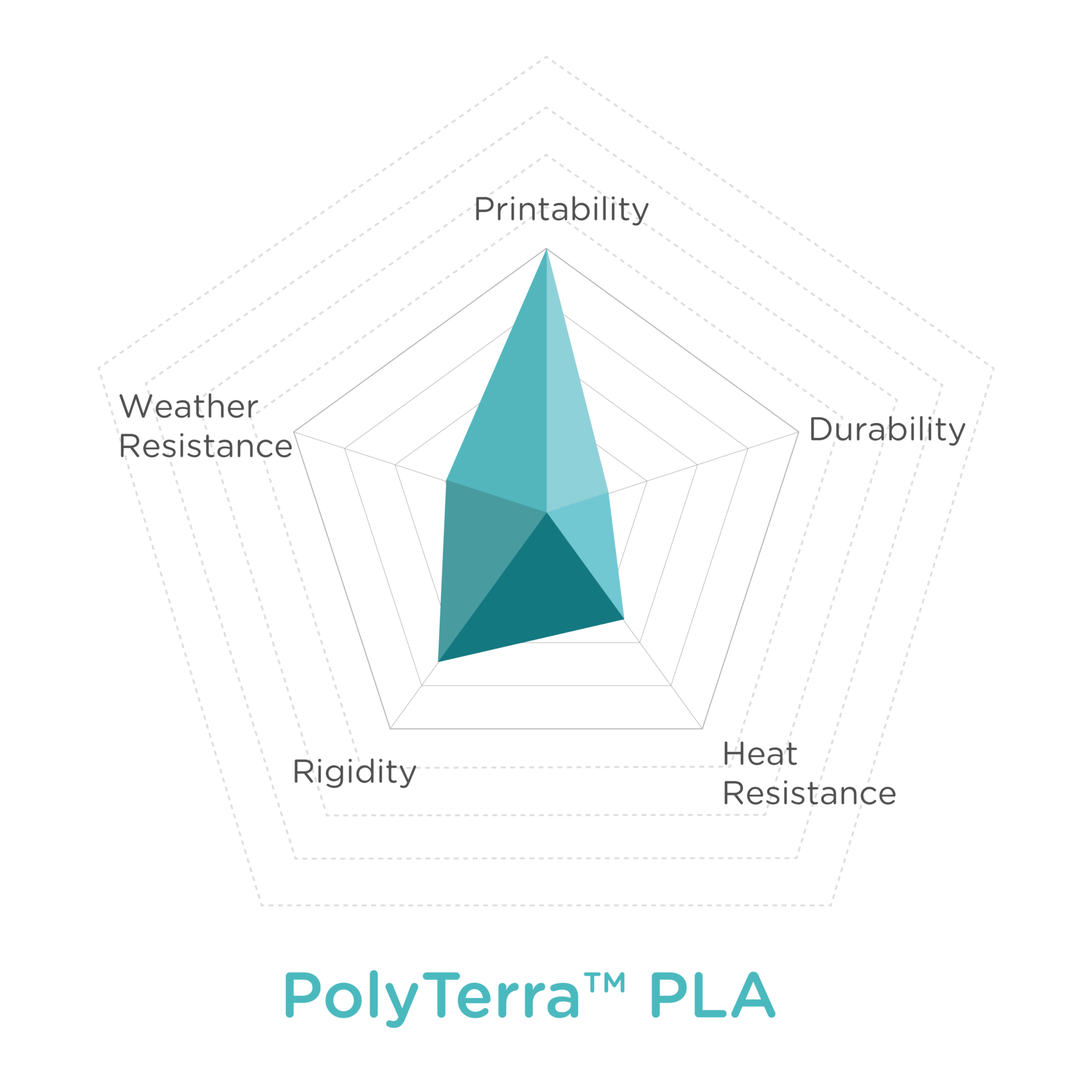

PolyTerra™ PLA

Eco-Friendly PLA

A World of Color & Effects

A World of Color & Effects

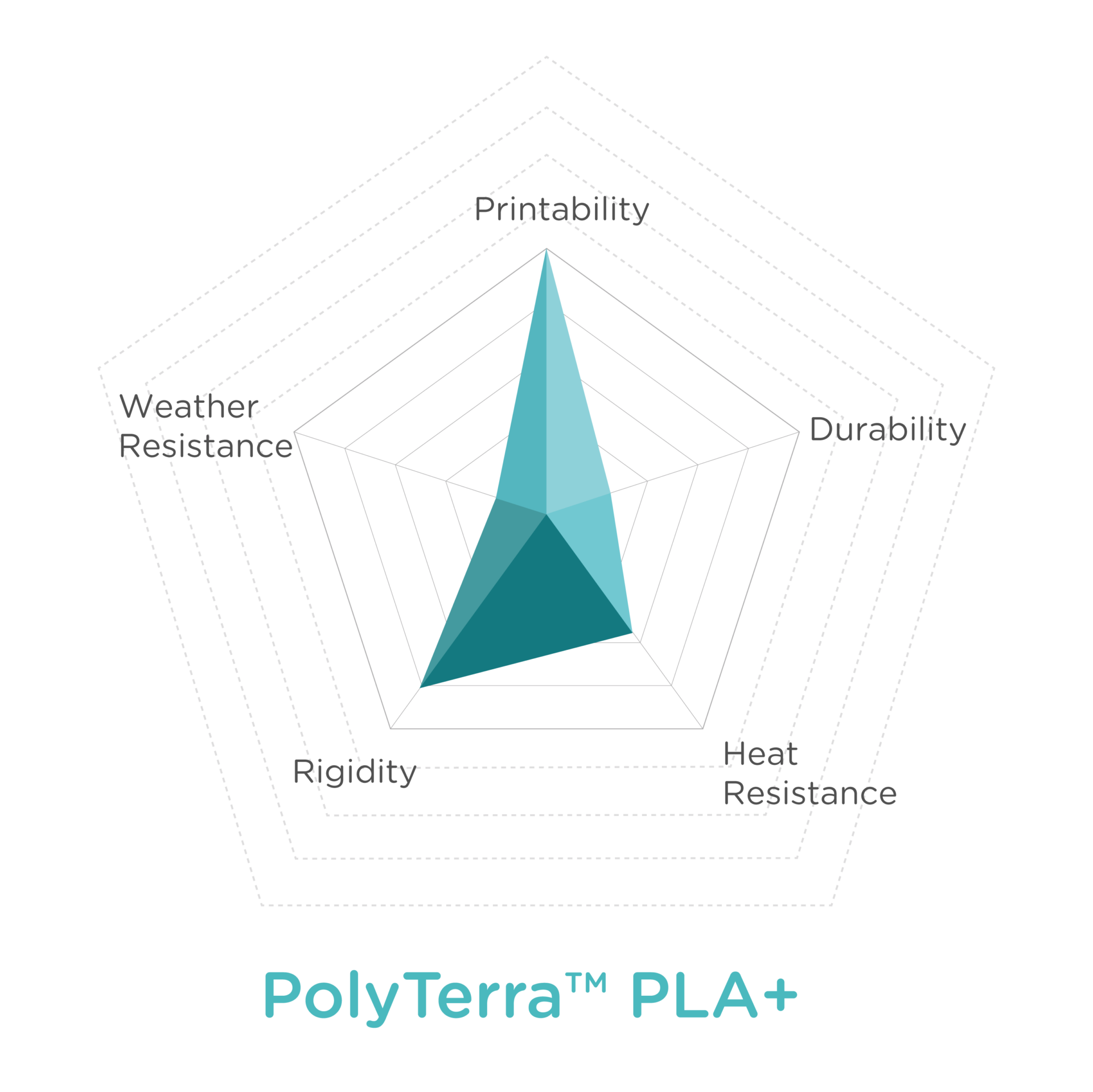

PolyTerra™ PLA+

Improved Toughness PolyTerra™

Satin Finish

Satin Finish

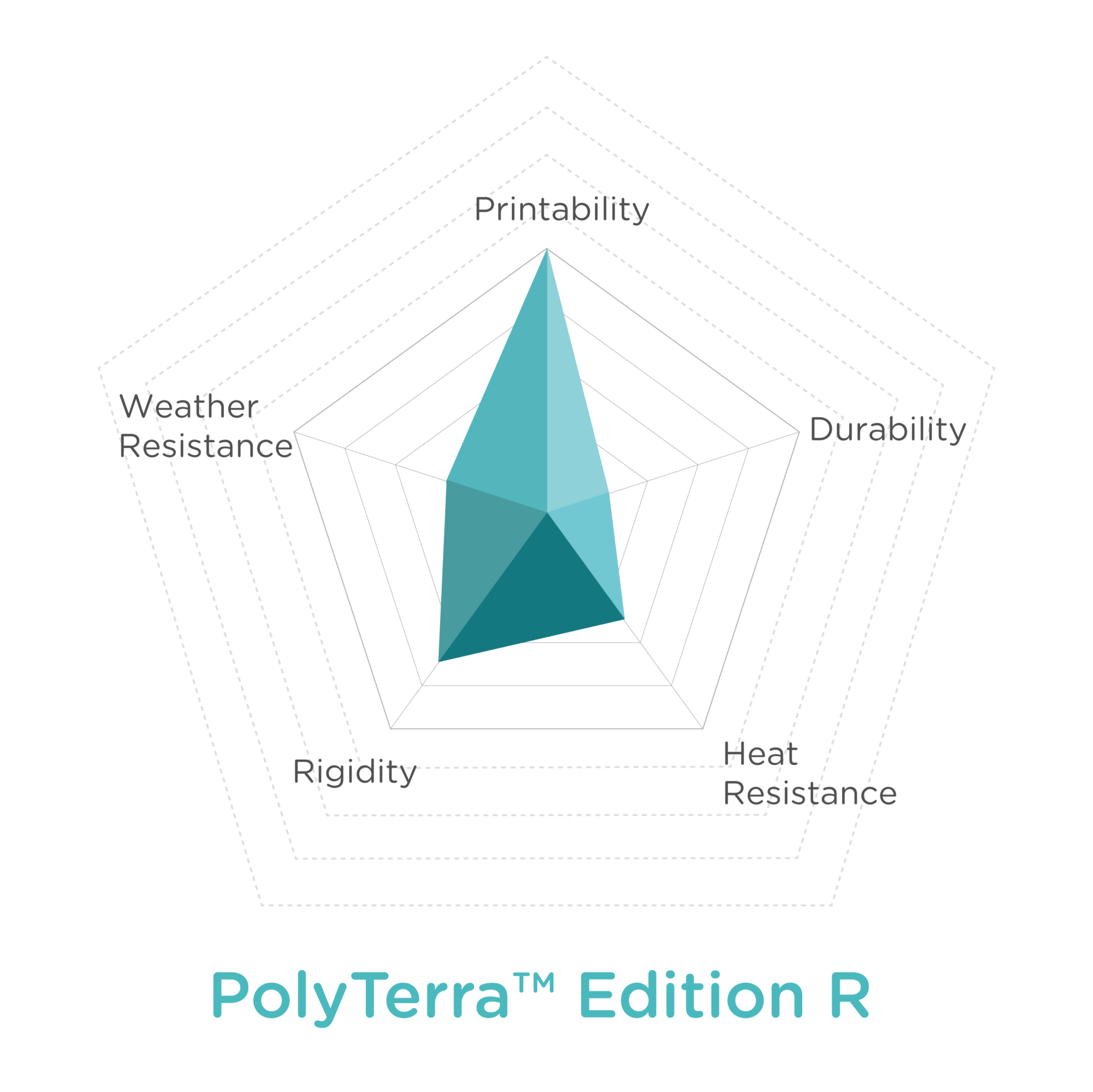

PolyTerra™ Edition-R

Matte Black

Recycled PLA

Recycled PLA

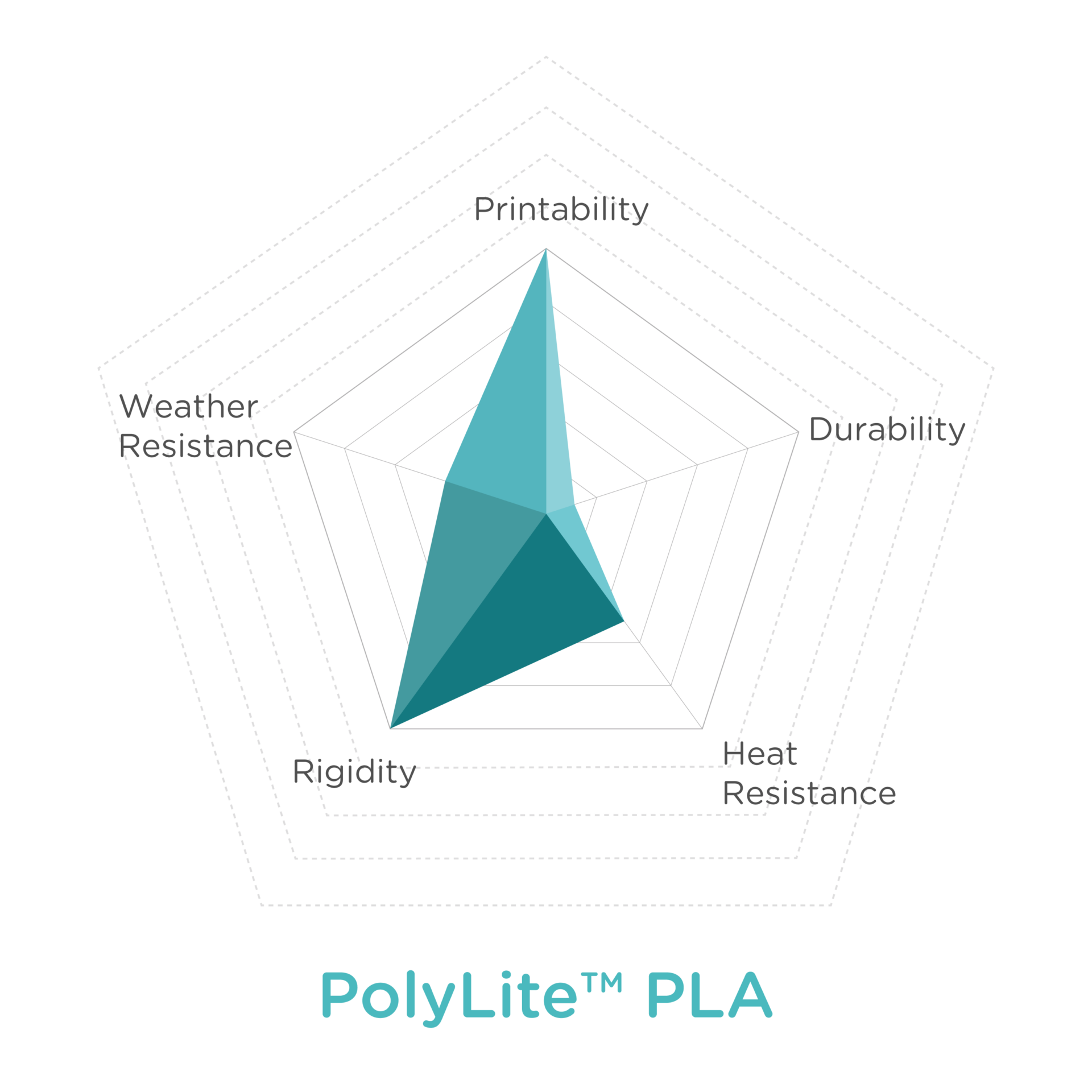

PolyLite™ PLA

High Quality PLA

Rigid & Reliable

Rigid & Reliable

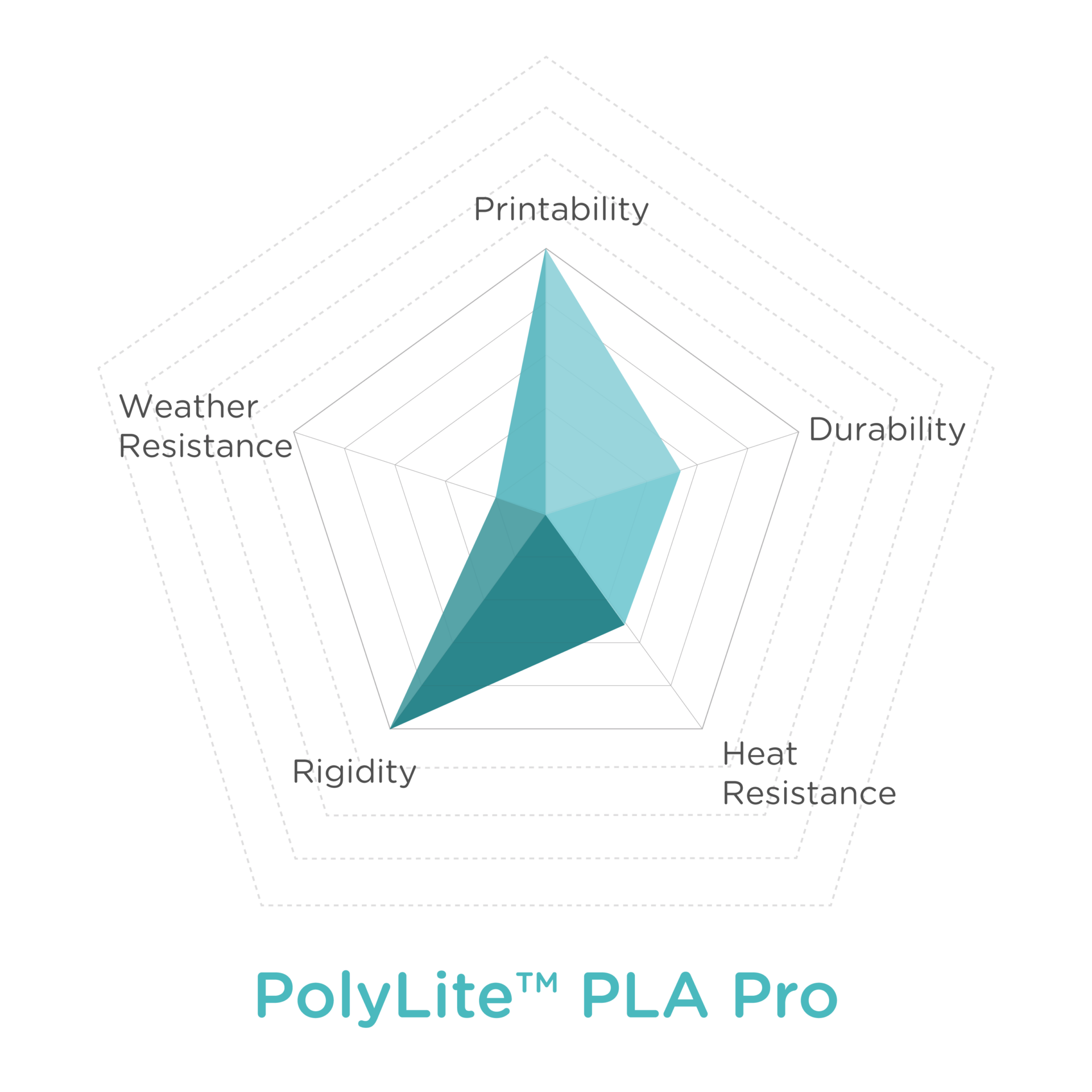

PolyLite™ PLA Pro

PLA for Professionals

Reliable & Repeatable

Reliable & Repeatable

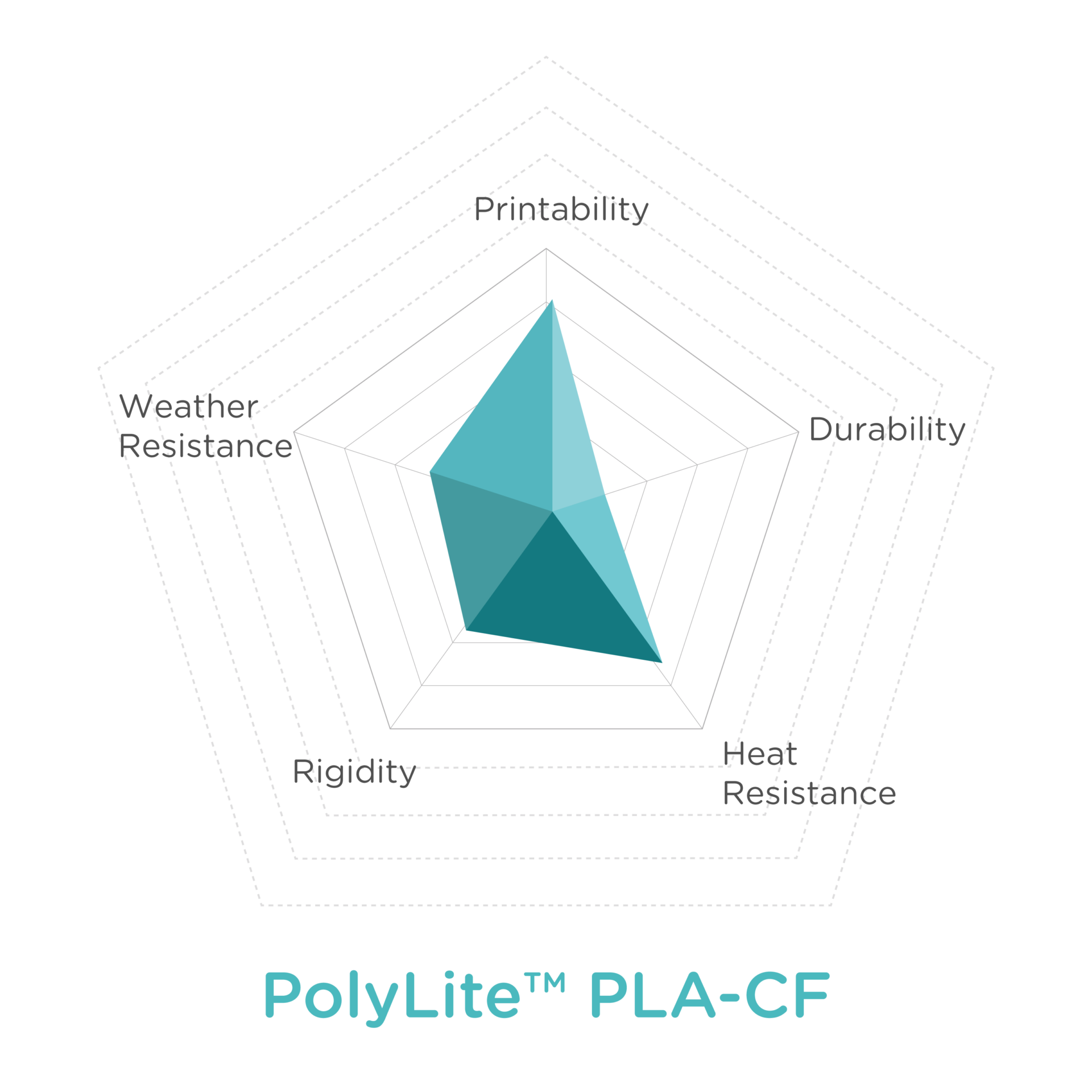

PolyLite™ PLA-CF

Carbon Fiber Reinforced PLA

Dimensionally Accurate

Dimensionally Accurate

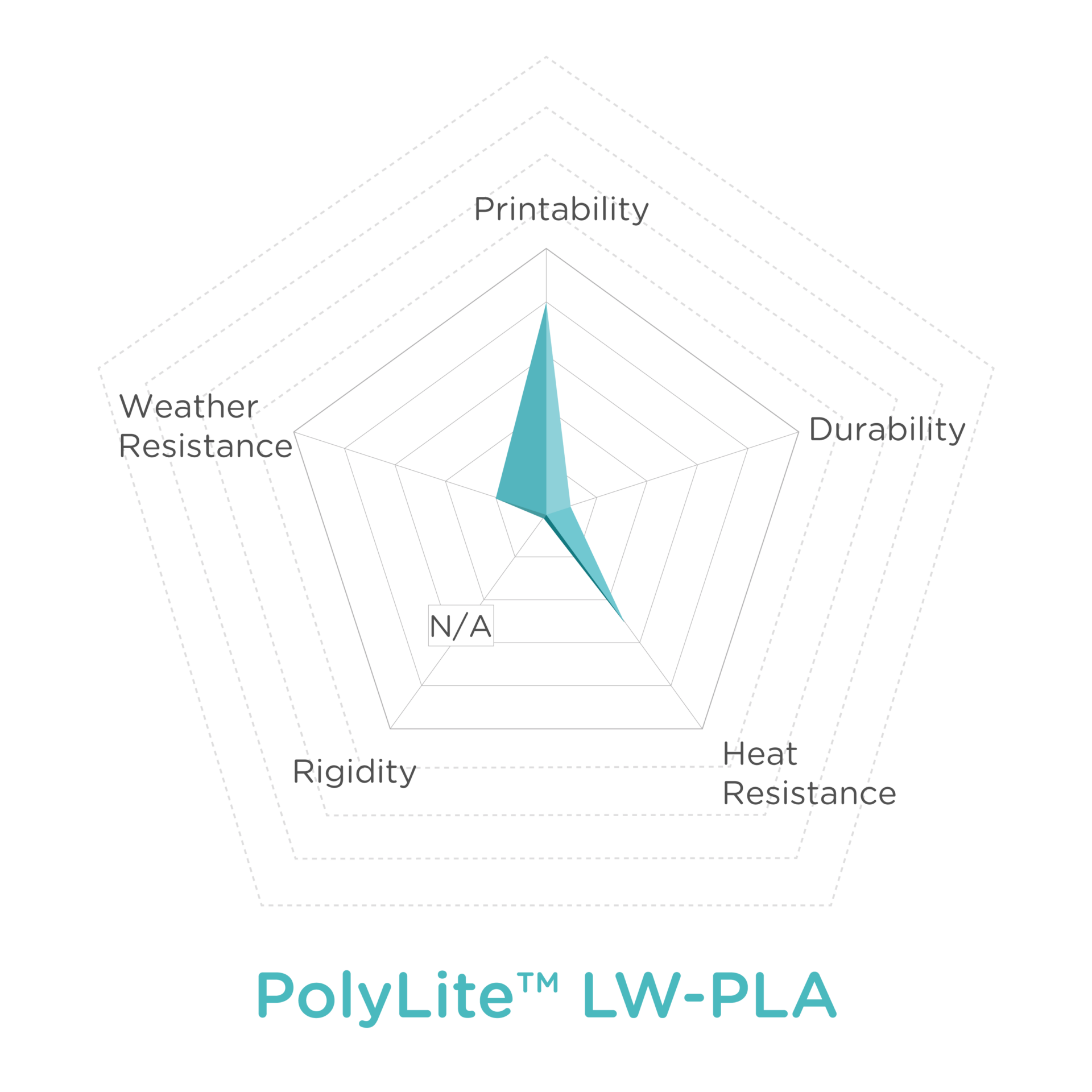

PolyLite™ LW-PLA

Light Weight PLA

70% density of regular PLA

70% density of regular PLA

PolyLite™ CosPLA

Easy to Sand

Great Paint Adhesion

Great Paint Adhesion

PolyMax™ PLA

Tougher than ABS

Prints like PLA

Prints like PLA

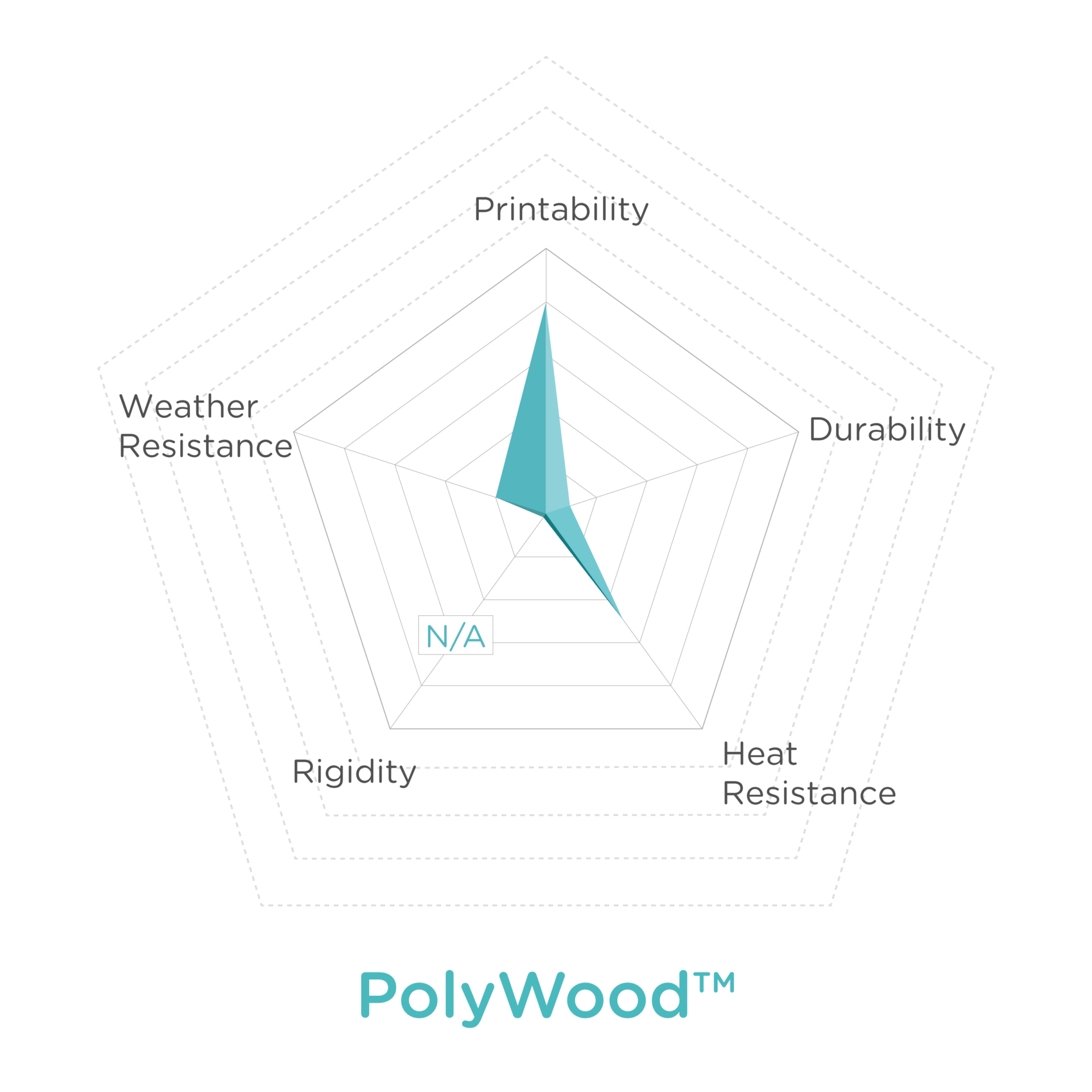

PolyWood™

Wood mimic PLA

Matte Surface

Matte Surface

Polymaker Draft PLA

Bulk Pack PLA

Great Value

Great Value

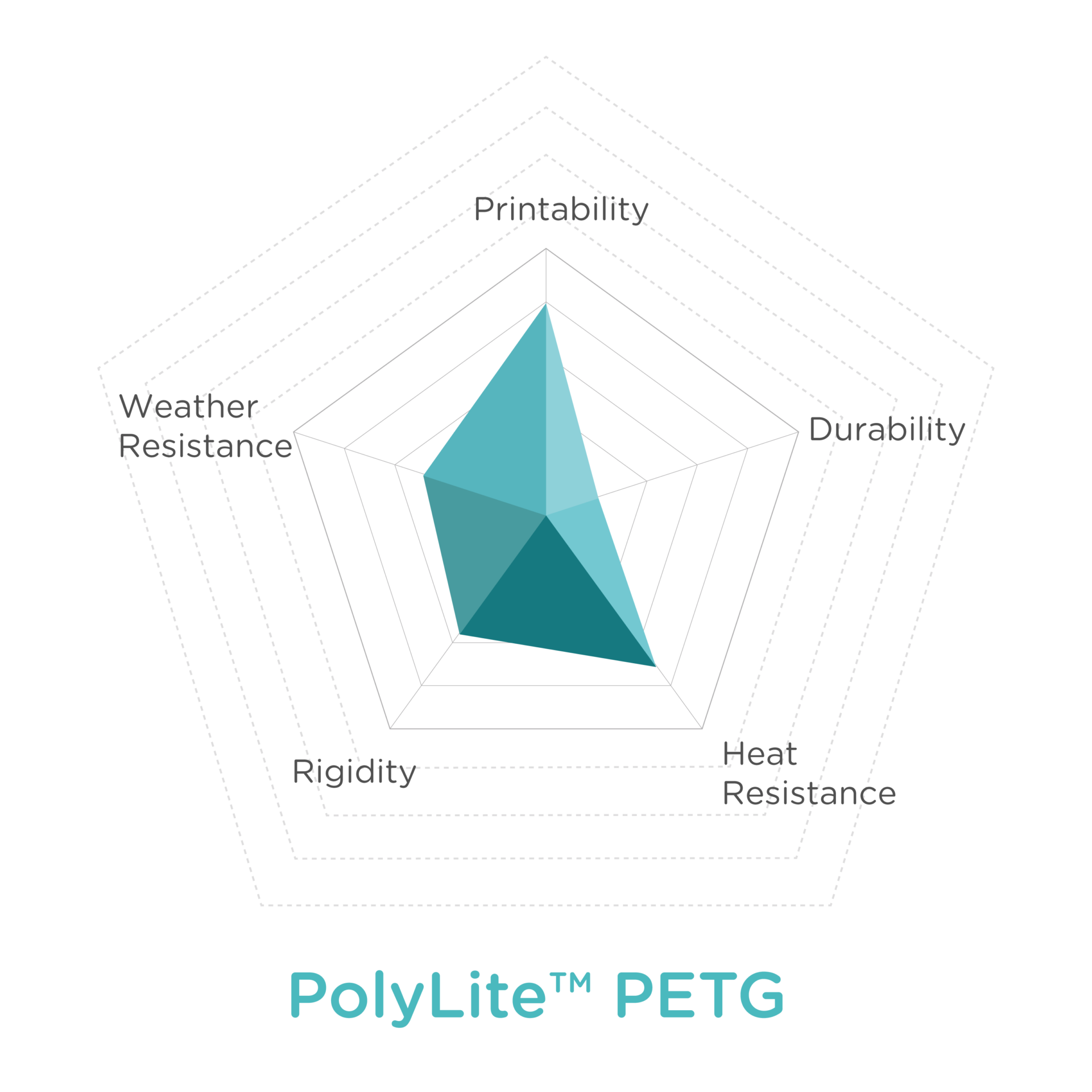

PolyLite™ PETG

Easy to Print

20°C heat resistance over PLA

20°C heat resistance over PLA

PolyMax™ PETG

Tough PETG

Nano Reinforcement™ Technology

Nano Reinforcement™ Technology

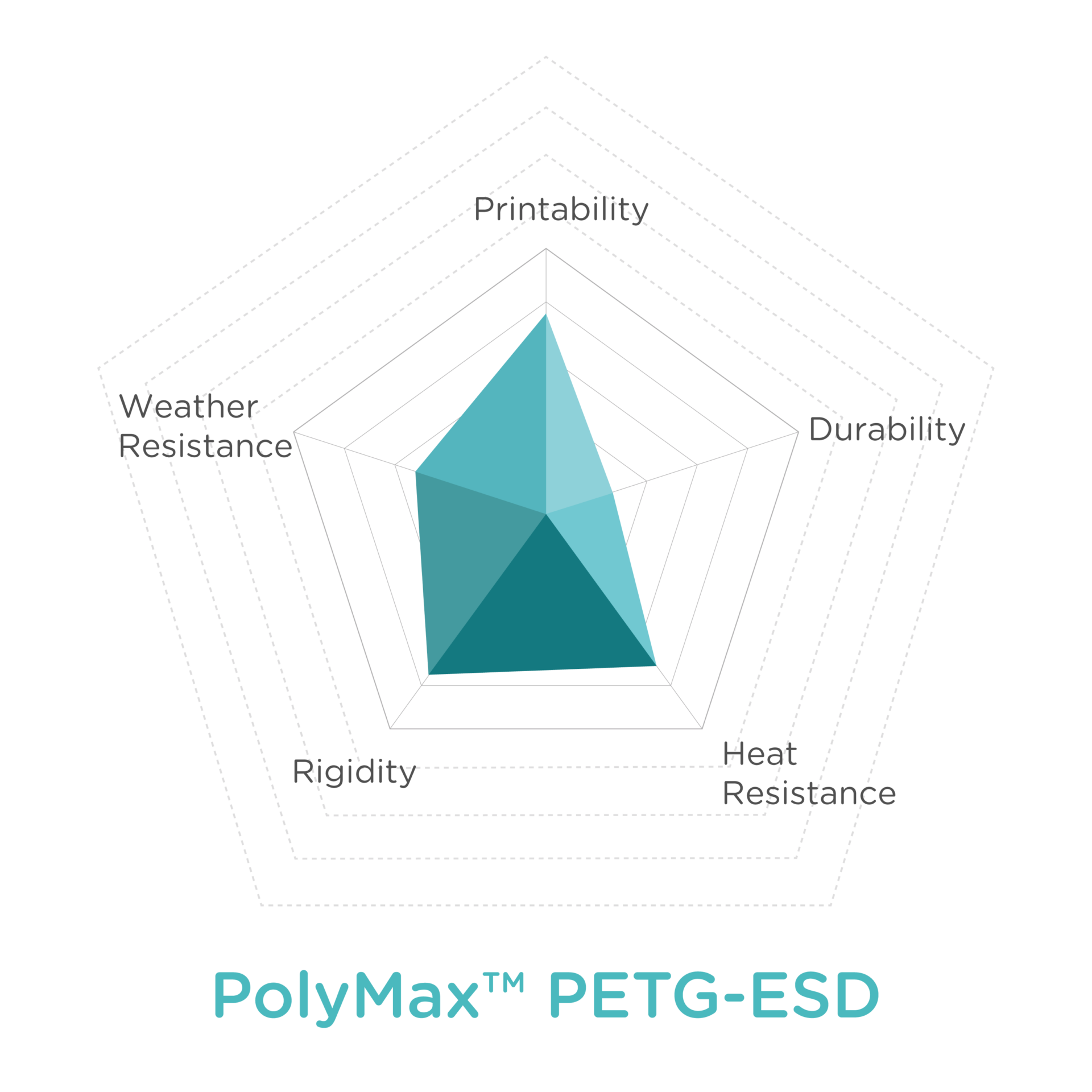

PolyMax™ PETG-ESD

ESD-Safe

Low Surface Resistivity

Low Surface Resistivity

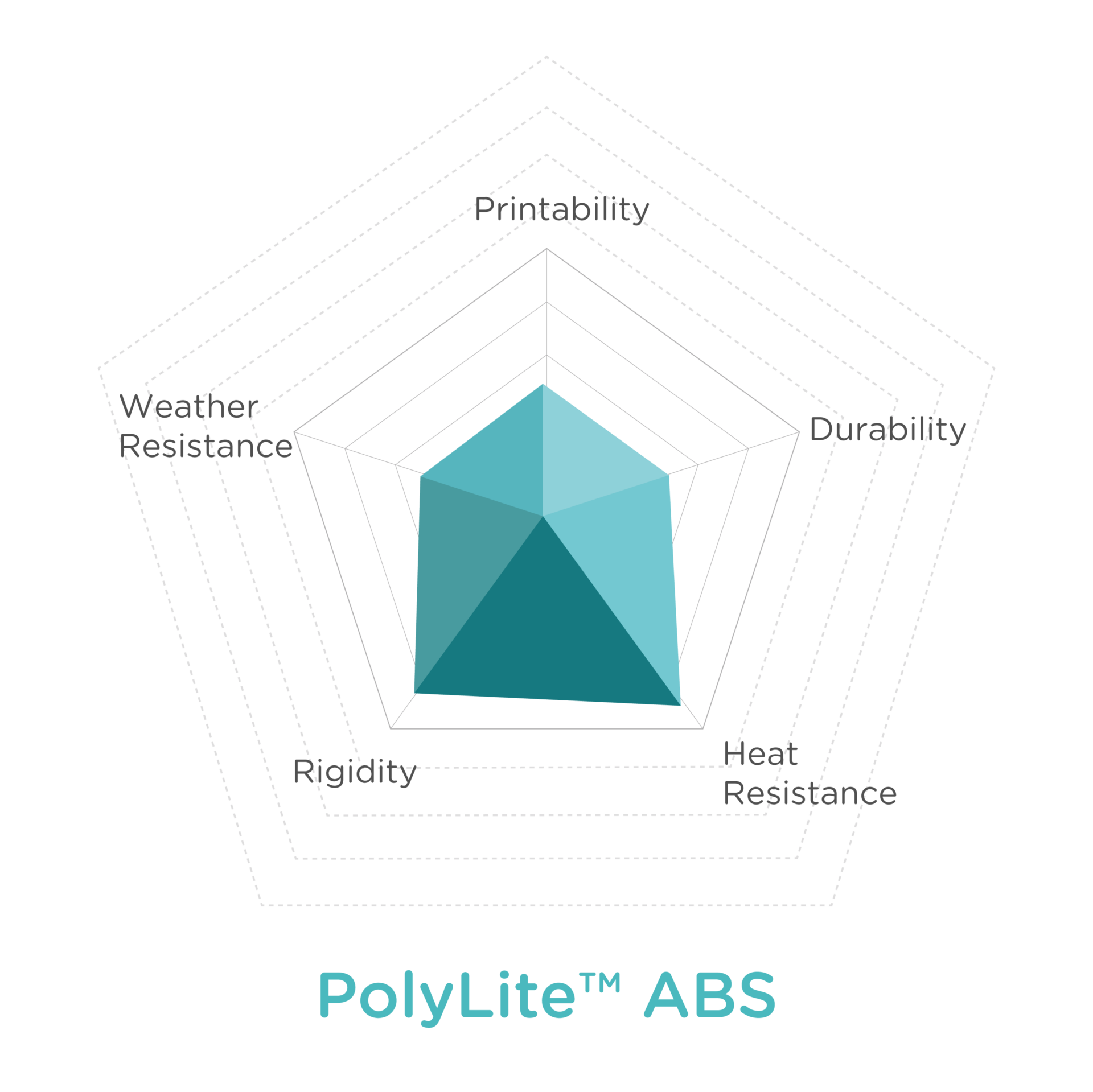

PolyLite™ ABS

Low Odor ABS

Strong & Durable

Strong & Durable

PolyLite™ ASA

Weather Resistant

UV Stable

UV Stable

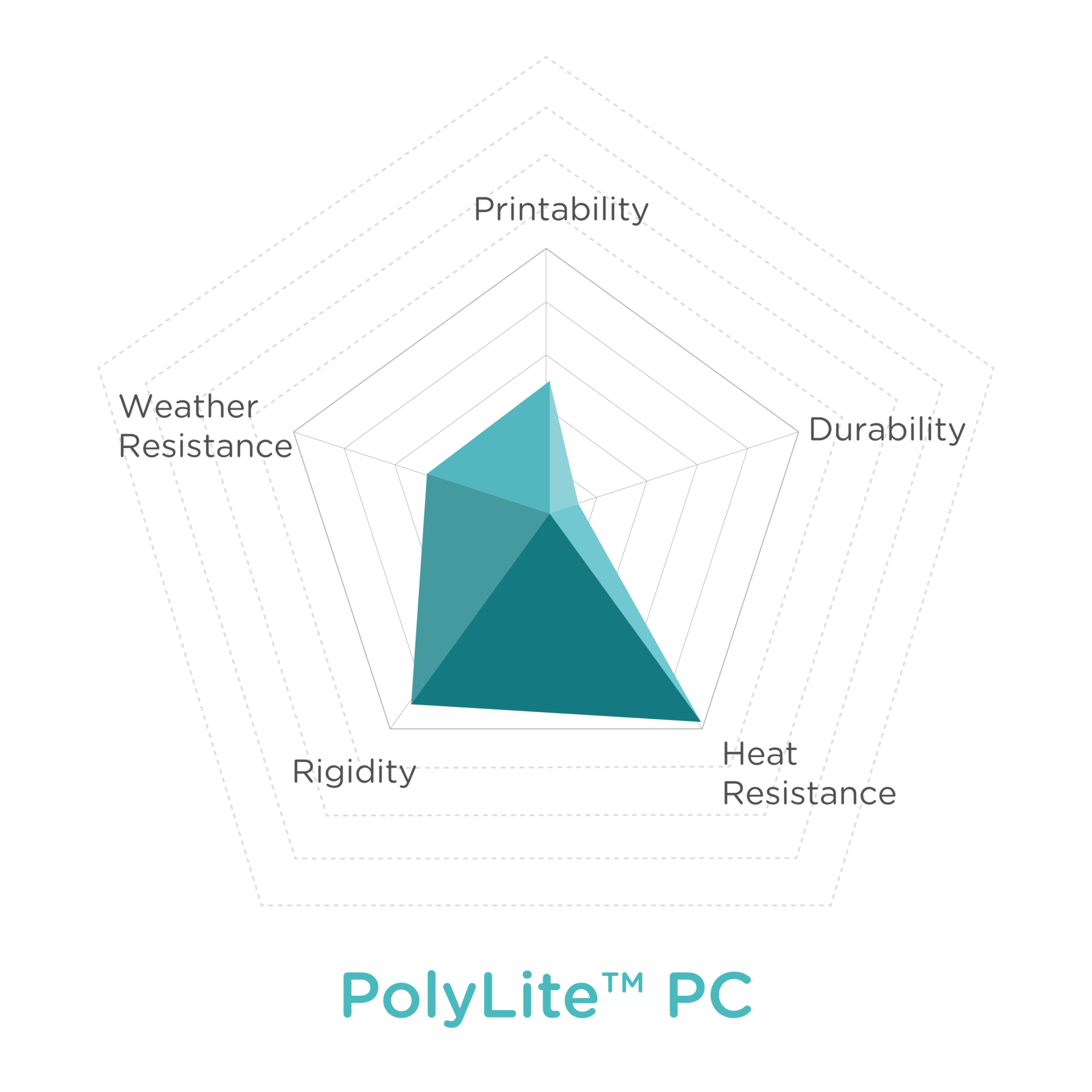

PolyLite™ PC

Naturally Transparent

Incredibly Stiff

Incredibly Stiff

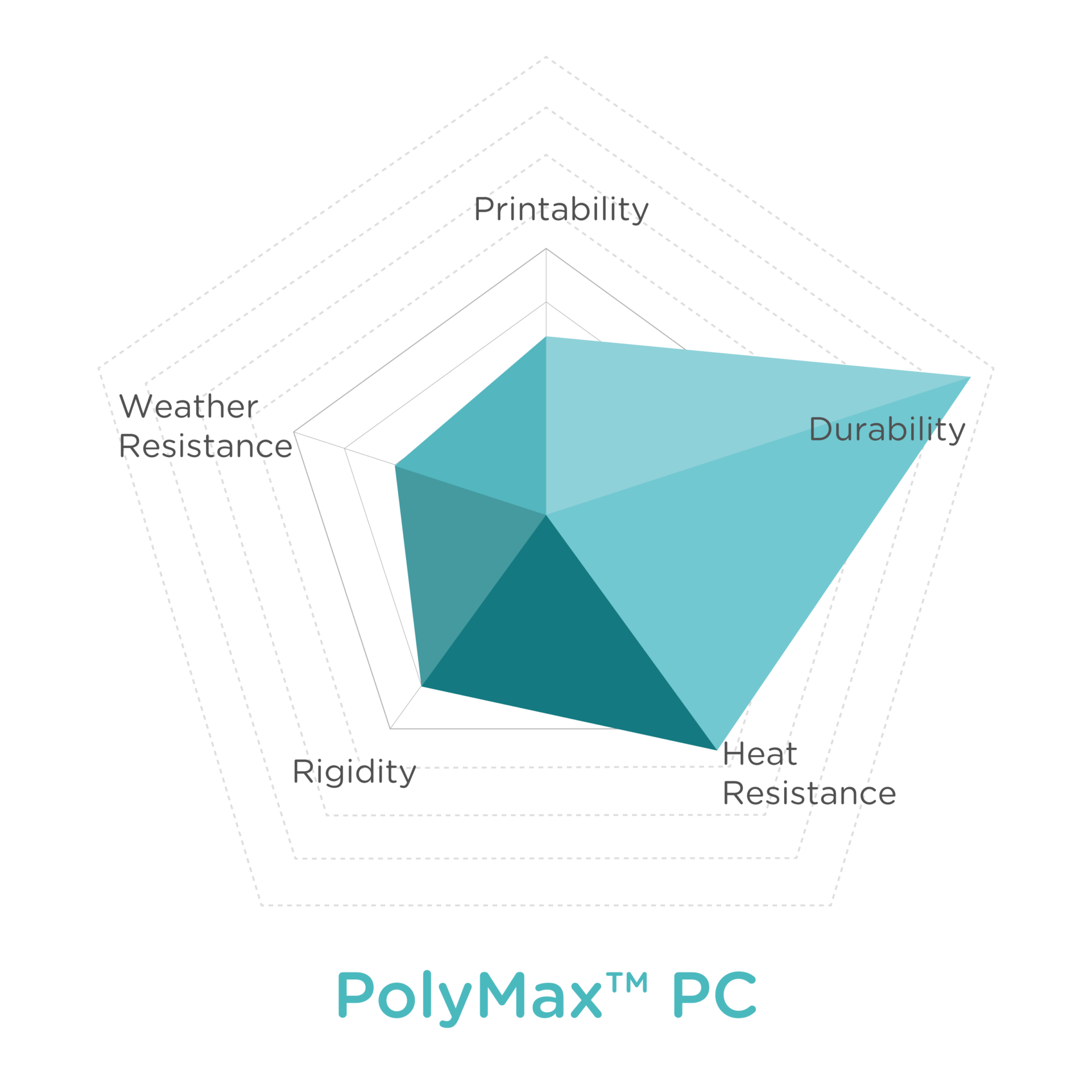

PolyMax™ PC

Incredibly Tough

Heat Resistant

Heat Resistant

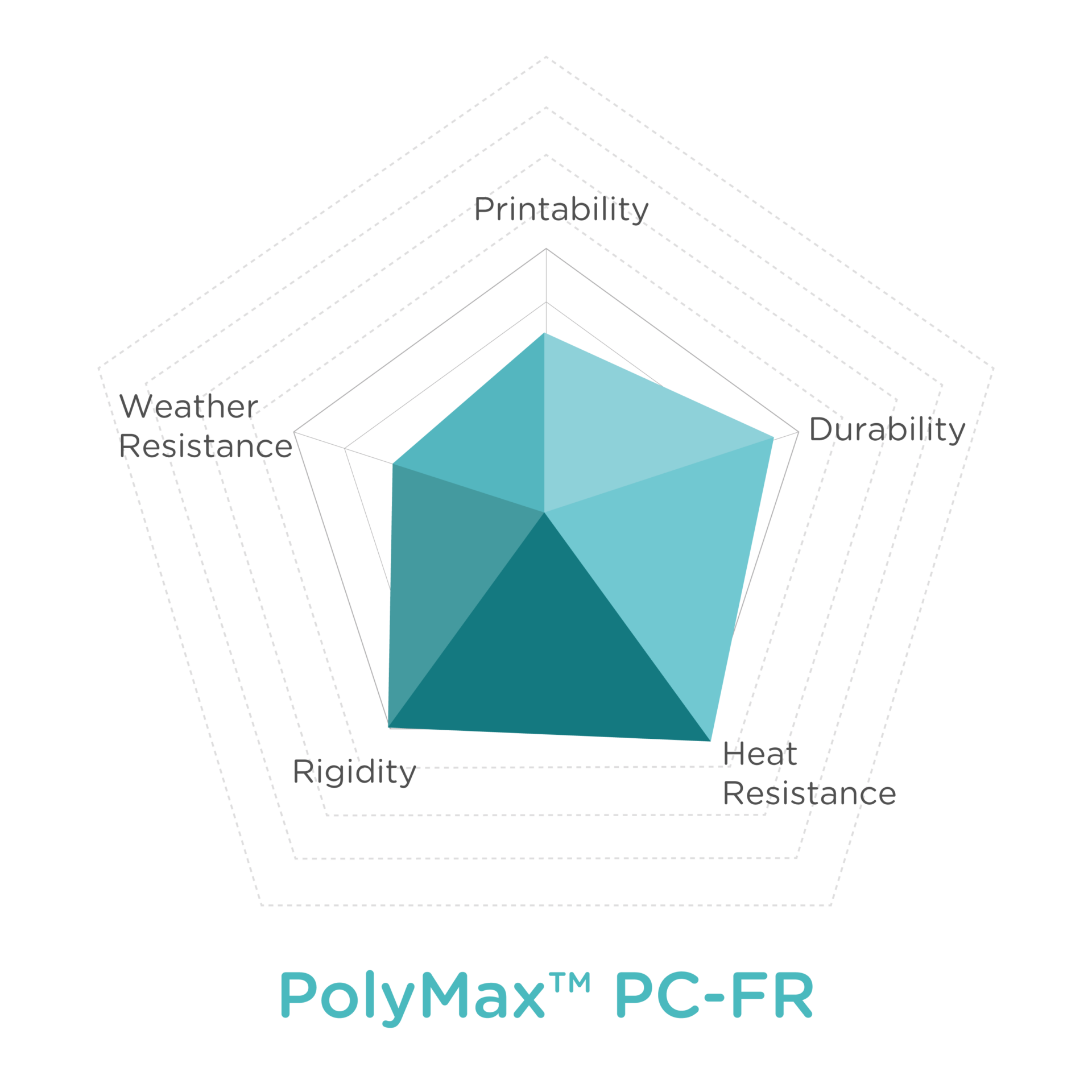

PolyMax™ PC-FR

Fire Retardant

Tough PC

Tough PC

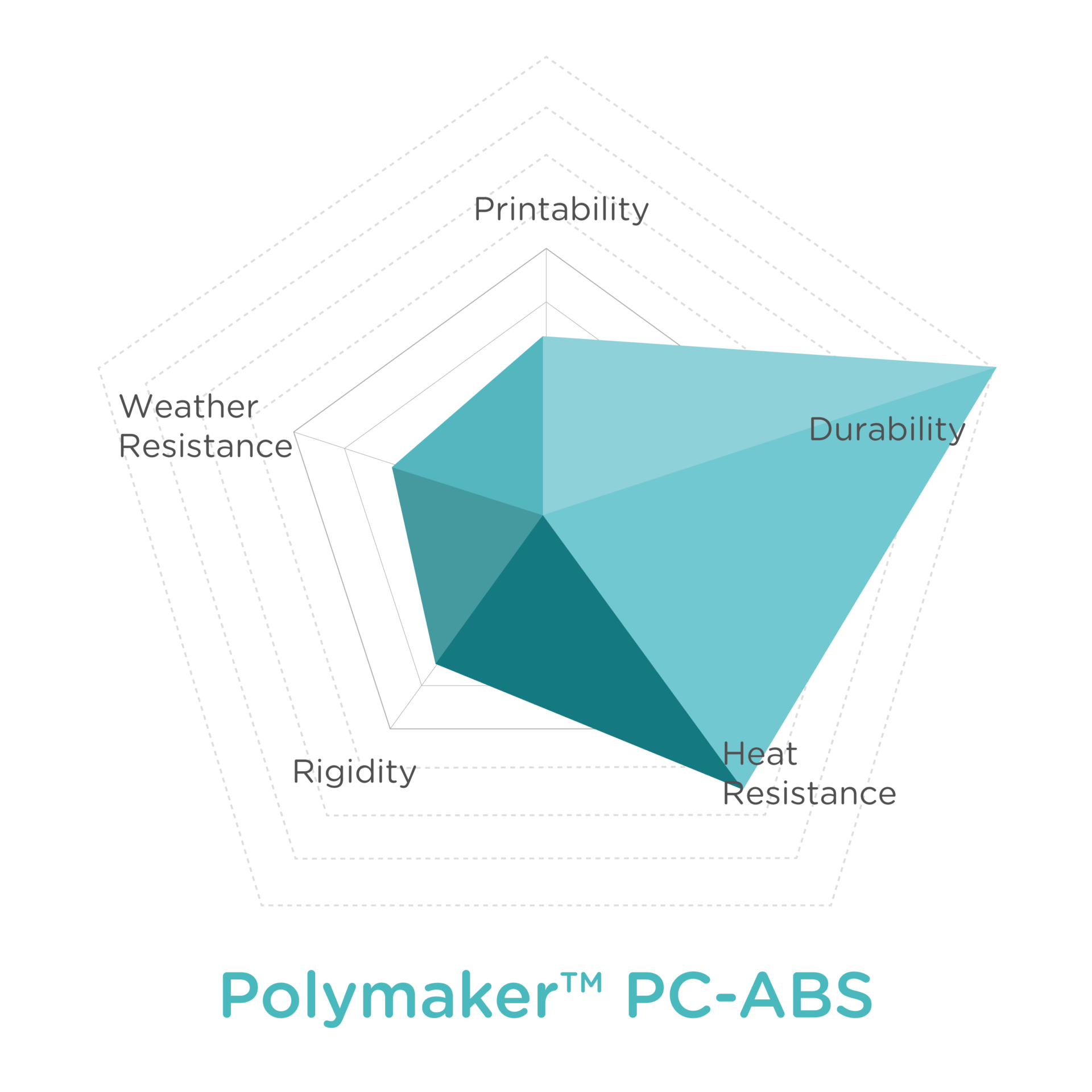

Polymaker PC-ABS

Excellent Mechanical Properties

Tough & Impact Resistant

Tough & Impact Resistant

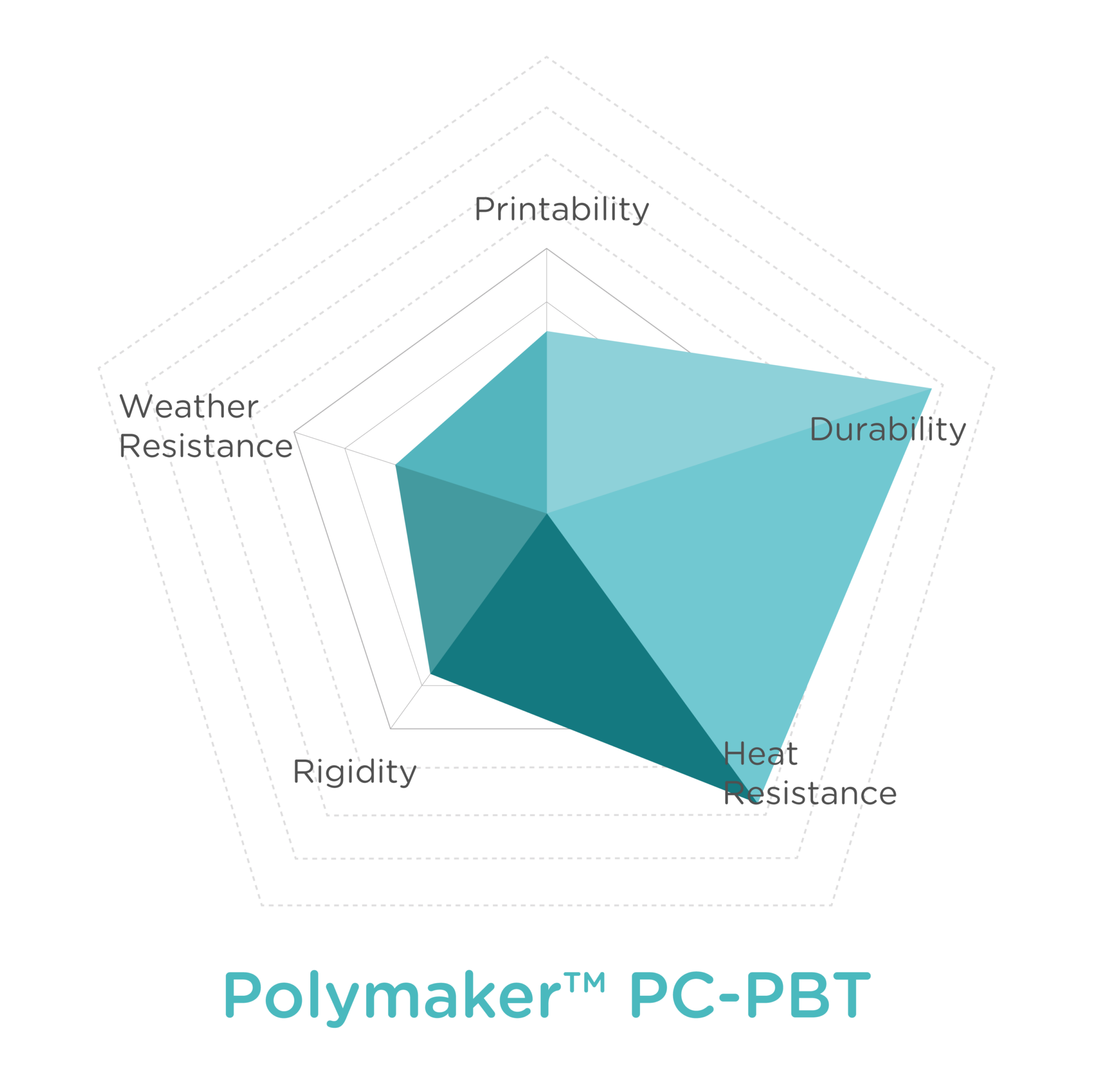

Polymaker PC-PBT

Tough in Low Temperatures

Chemically Resistant

Chemically Resistant

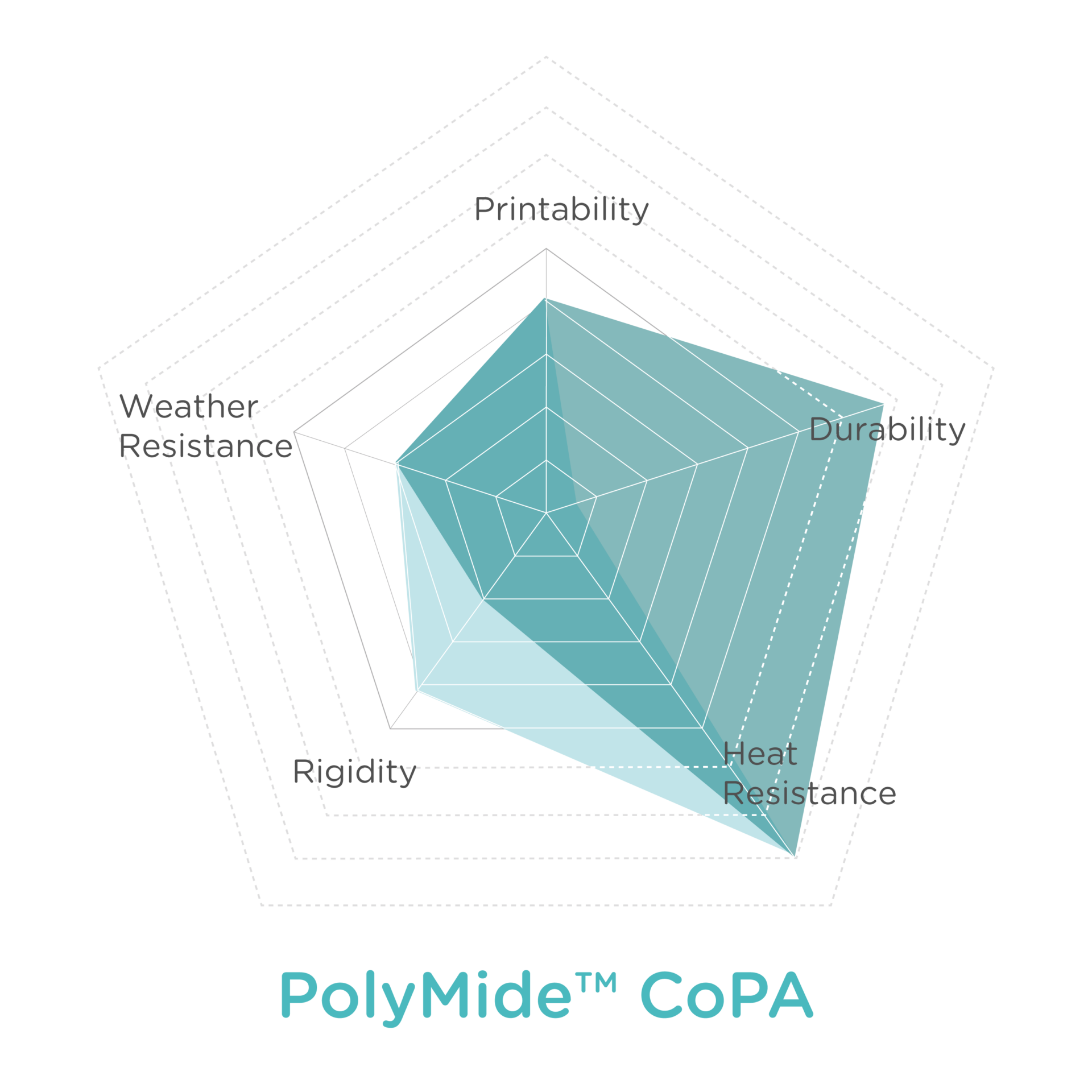

PolyMide™ CoPA

Heat Resistant 180°C

Extremely Tough

Extremely Tough

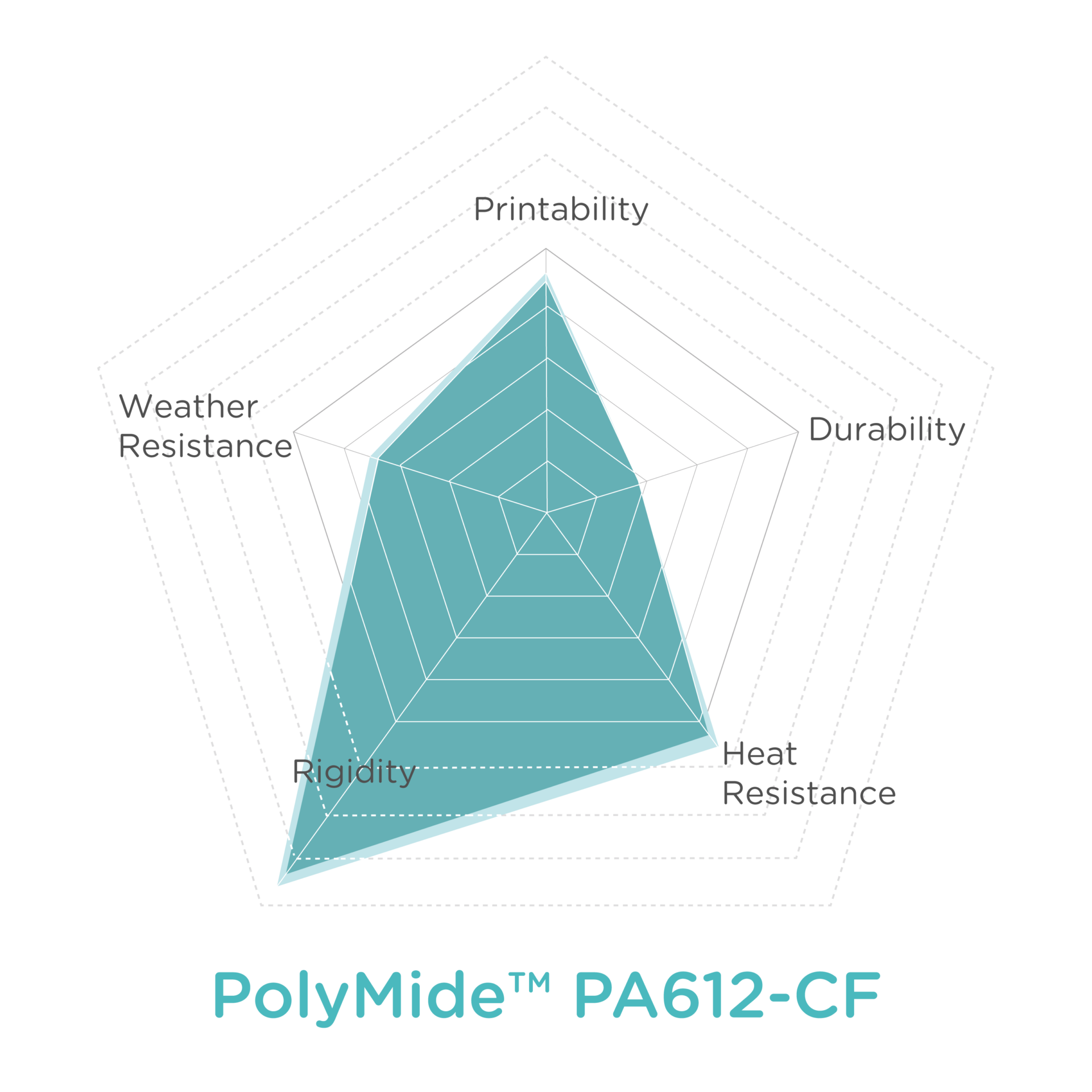

PolyMide™ PA612-CF

Less Moisture Sensitive than PA6

Stronger than PA12

Stronger than PA12

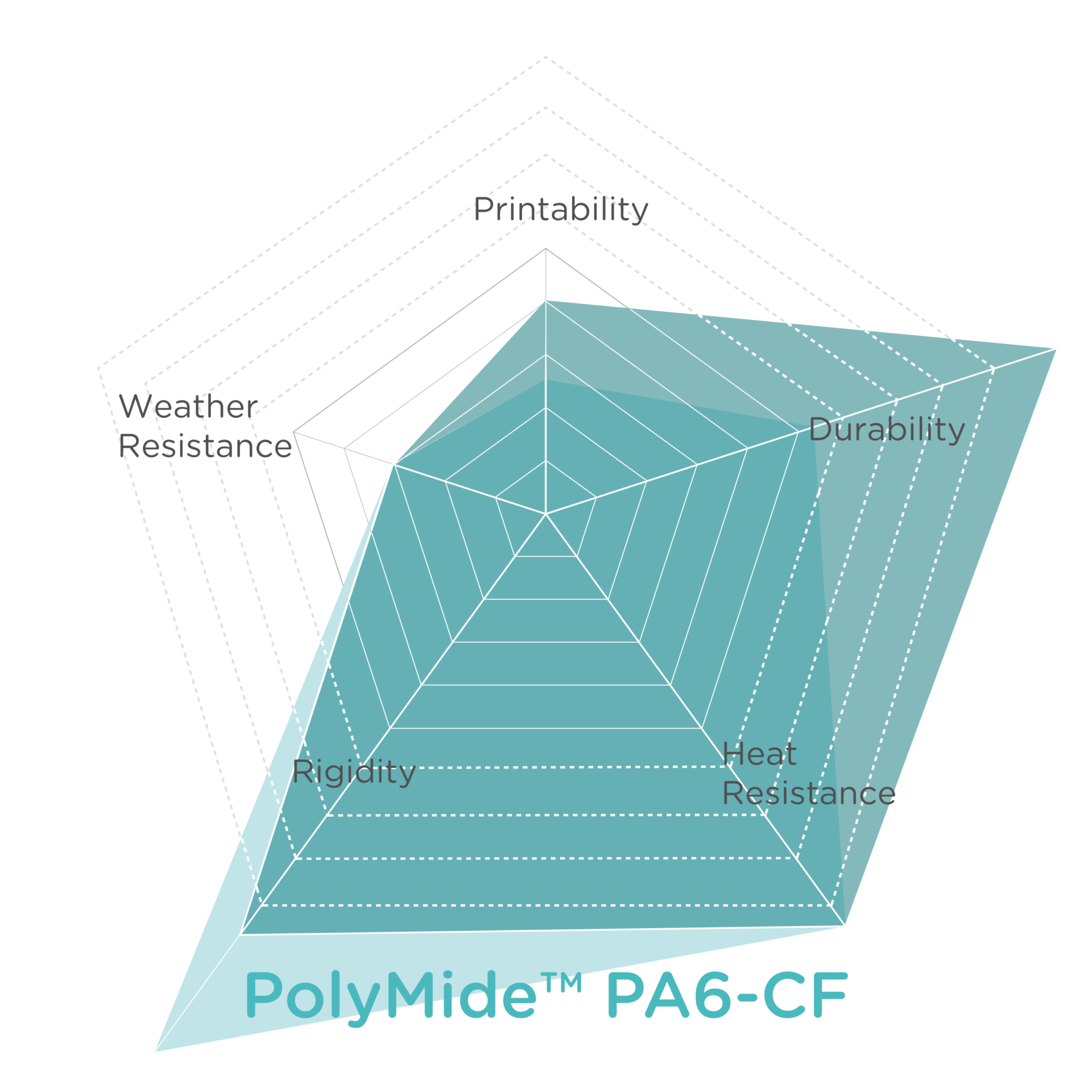

PolyMide™ PA6-CF

Incredible Strength & Toughness

Extreme Heat Resistance

Extreme Heat Resistance

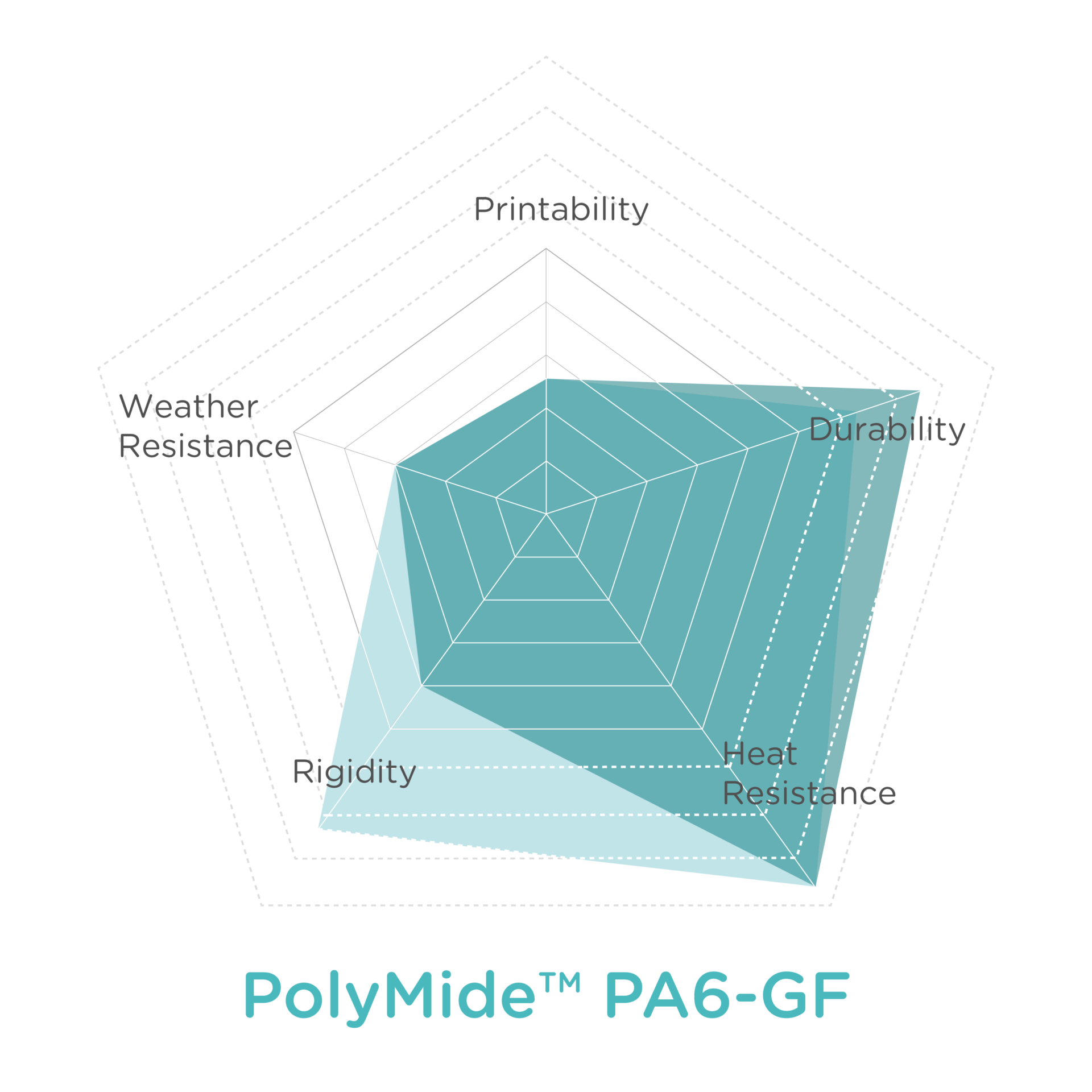

PolyMide™ PA6-GF

Extremely Stiff

Highly Processable

Highly Processable

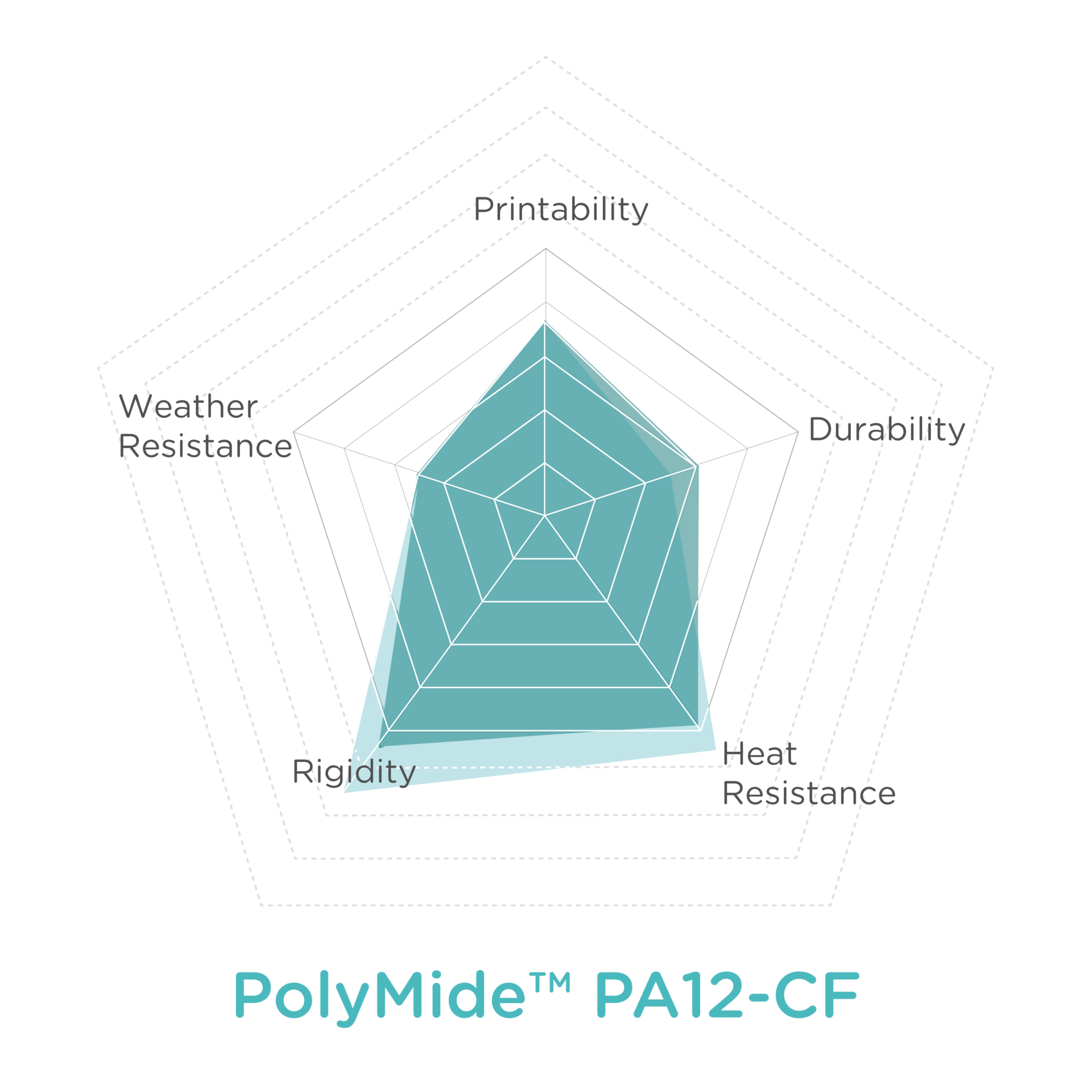

PolyMide™ PA12-CF

Easy to Print Nylon

Not Moisture Sensitive

Not Moisture Sensitive

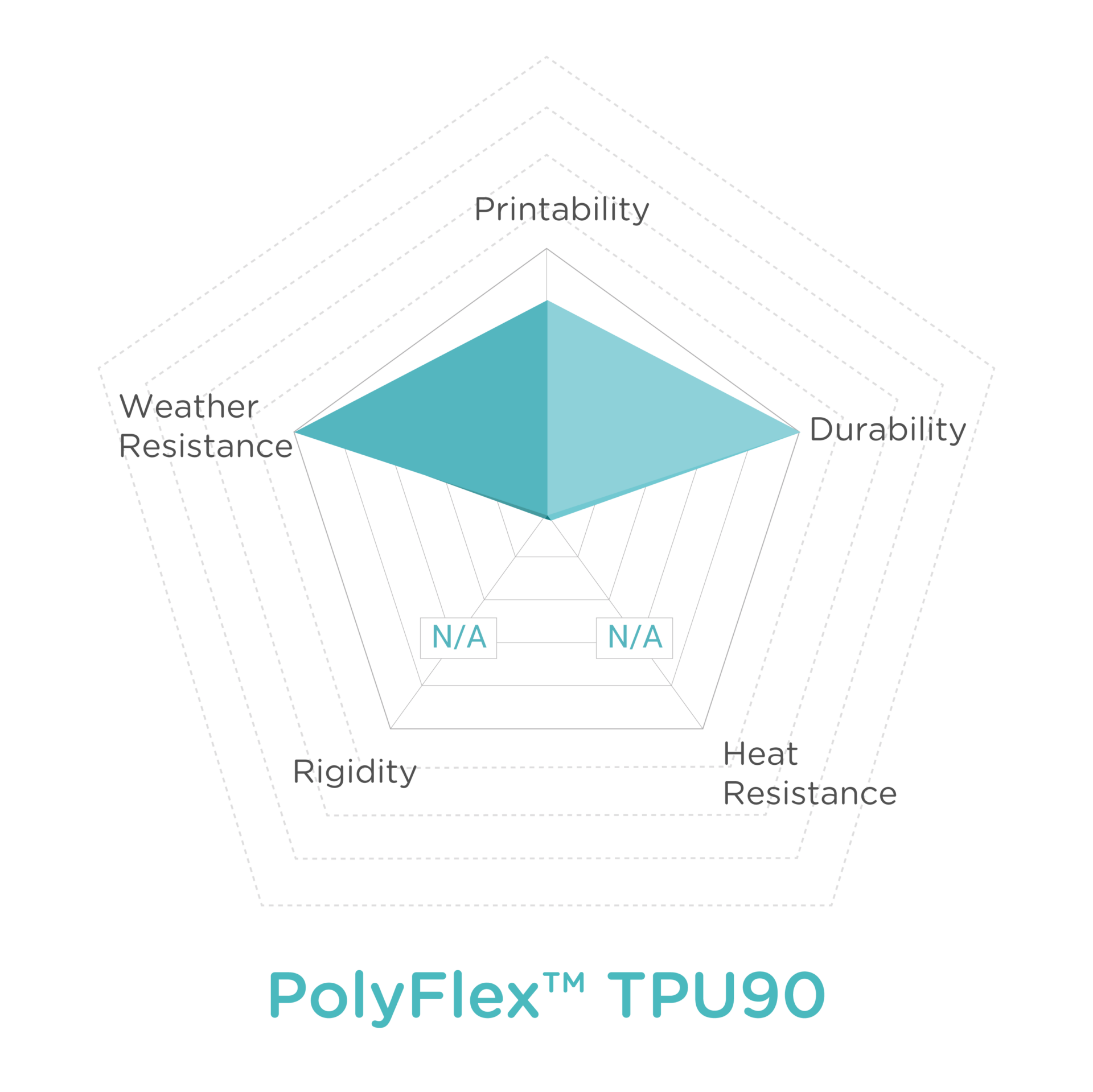

PolyFlex™ TPU90

Skin Contact Safe

UV Stable

UV Stable

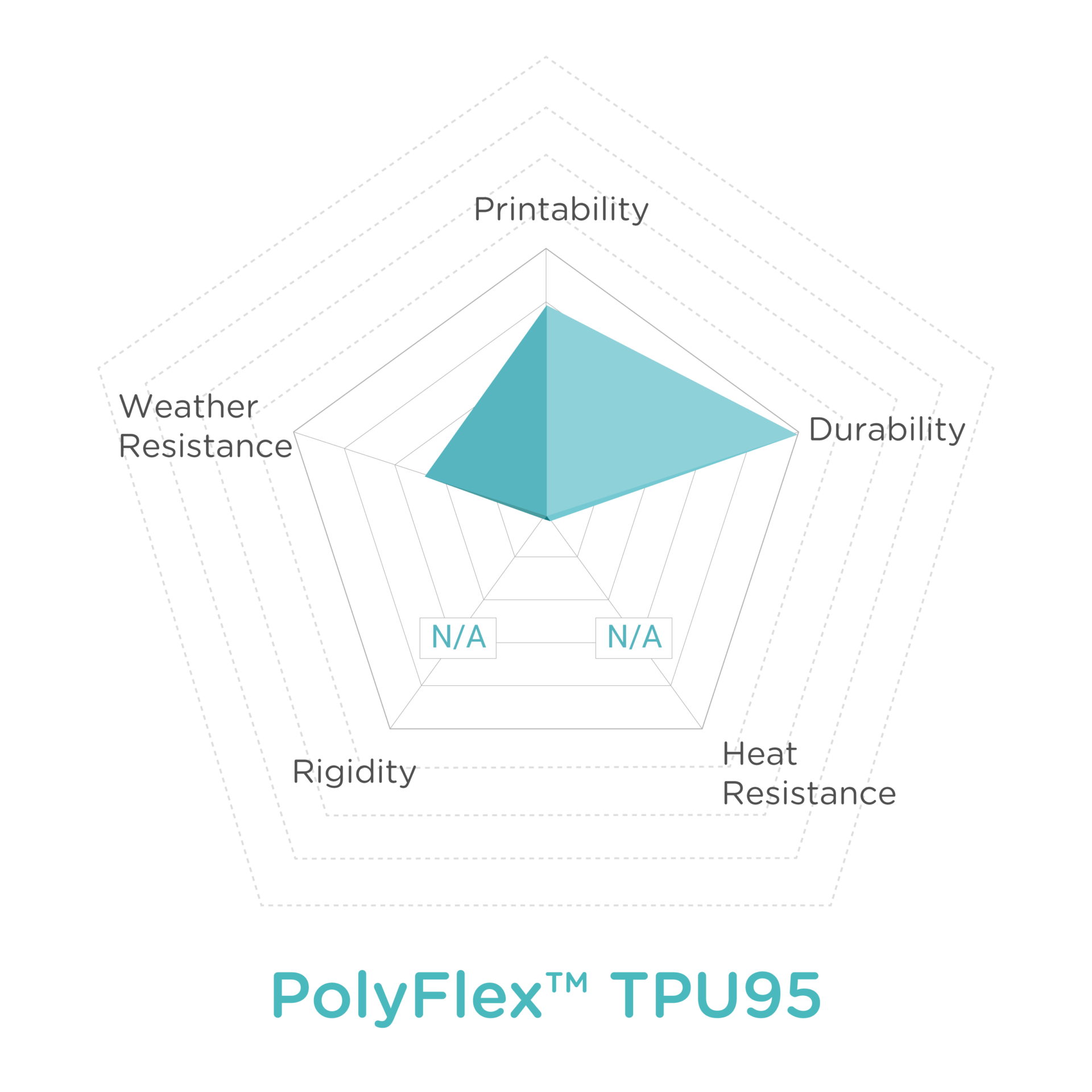

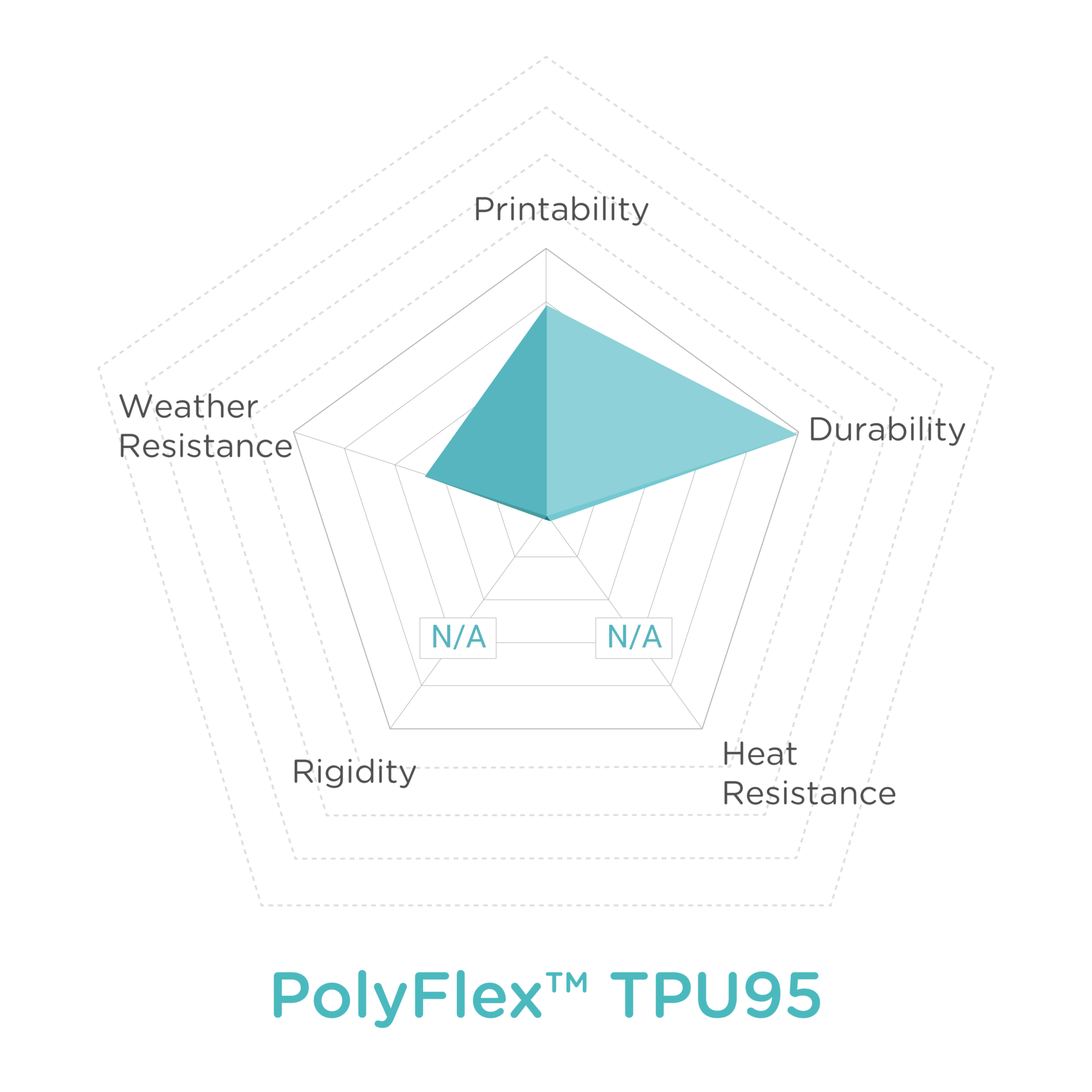

PolyFlex™ TPU95

Flexible & Printable Shore

Hardness 95A

Hardness 95A

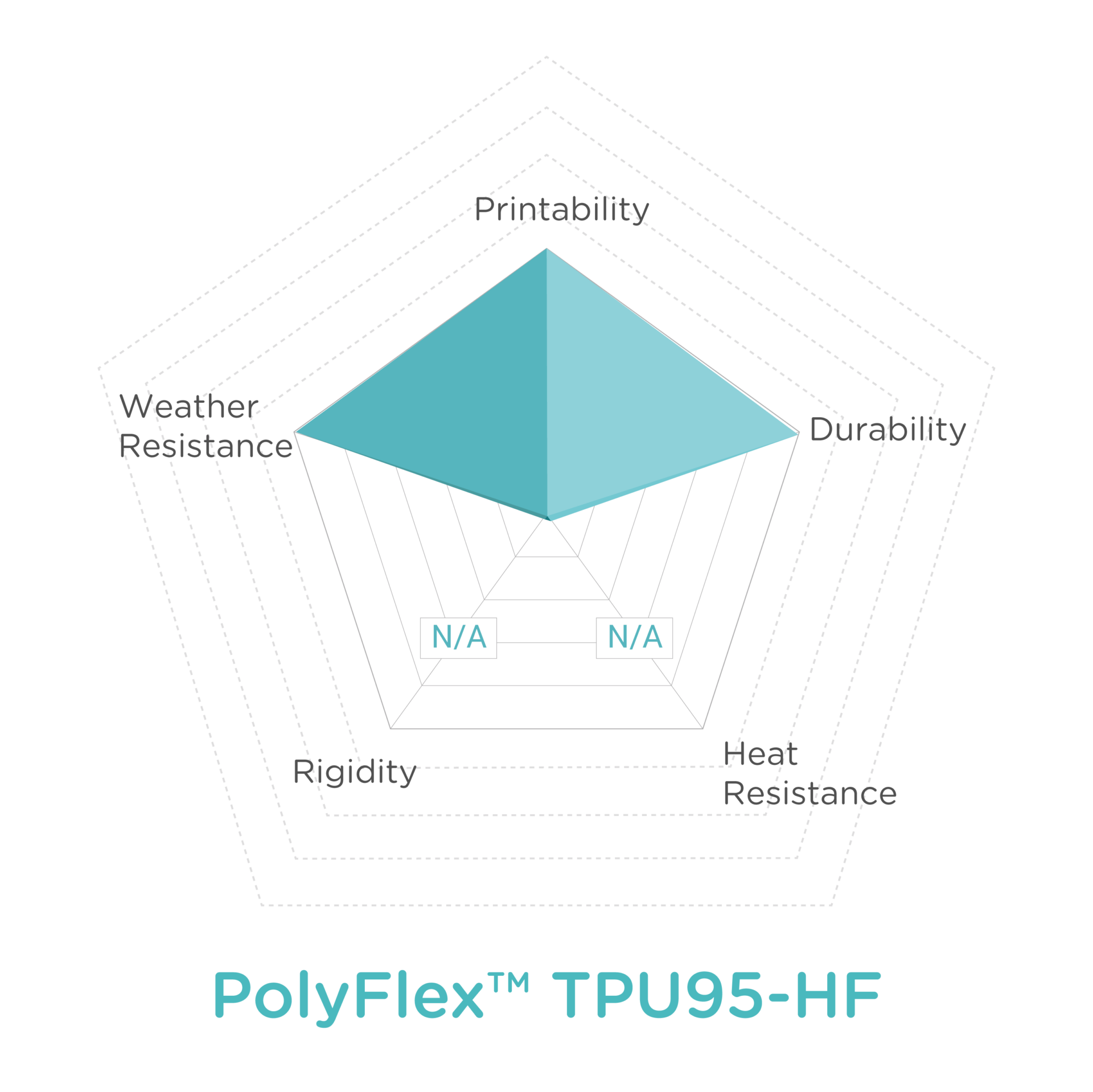

PolyFlex™ TPU95-HF

High Speed Flexible

Easy to Print

Easy to Print

PolySmooth™

Alcohol Smoothable

Remove layer lines

Remove layer lines

PolyCast™

Very Clean Burn Out

Ash Residue < 0.003%

Ash Residue < 0.003%

PolyDissolve™ S1

Water Dissolvable Support

Compatible with PLA, Nylon, TPU, PVB

Compatible with PLA, Nylon, TPU, PVB

PolySupport™

Breakaway Support

Quick & Easy

Quick & Easy

PolySupport™ for PA12

Breakaway Support for PA12

No tools required

No tools required

Material Comparison

View our material charts to find the suitable filament for your application.

For more detailed technical data visit our webapp:Full Technical Data Comparison

For more detailed technical data visit our webapp:Full Technical Data Comparison

Dry state

Wet state

Printability

The printability of the material is defined by its ease of use and equipment required.

Rigidity

The rigidity of the material is defined by its modulus:Young’s modulus

ISO 527, GB/T 1040.

ISO 527, GB/T 1040.

Heat Resistance

The heat resistance of the material is defined by its VST: Vicat Softening temperature

ISO 306 GB/T 1633.

ISO 306 GB/T 1633.

Weather Resistance

The weather resistance of the material is defined by its UV resistance. The data provided is currently an estimation.

Durability

The durability of the material is defined by its resistance to impact:Charpy impact strength

ISO 179, GB/T 1043.A

ISO 179, GB/T 1043.A

*PolyMide™ PA6-CF and PolyMide™ PA6-GF heat resistance are defined by their HDT: Heat Deflection Temperature

ISO 75 0.45 MPa.

ISO 75 0.45 MPa.