CHINA UNVEILS THE WORLD’S LARGEST 3D PRINTED STRUCTURE

When it comes to 3D printing the ever- growing list of absolutely massive, large size 3D printing ventures is hard to ignore. You might remember Vulcan Pavilion which was record holder of the world’s biggest 3D printed structure in 2015 the Guinness World Records. Comprised of 1023 individual 3D printed units and standing at 8.08 meters long by 2.88 meters high. Well, they say that ‘records are made to be broken’ and thats exactly what happened in the 3D printing world. Beijing’s amazing 3D PRINTED Vulcan Pavilion has been ousted as the world’s largest 3D printed structure.

The new pavilion was officially awarded the Guinness World Record for largest 3D printed structure on August 20th, 2016. Beijing-based DeFacto was commissioned to design a structure for their client, Rise Education.

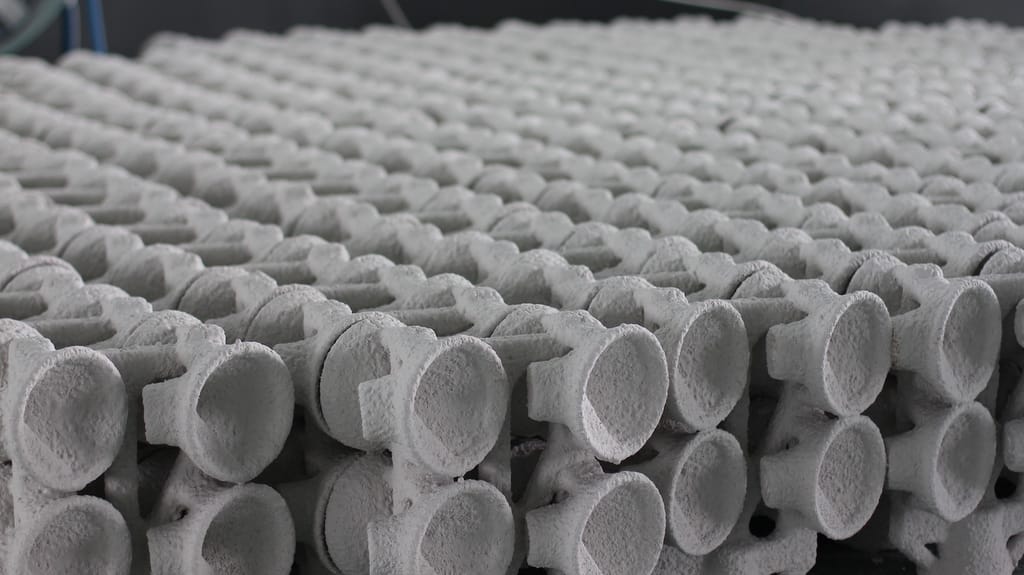

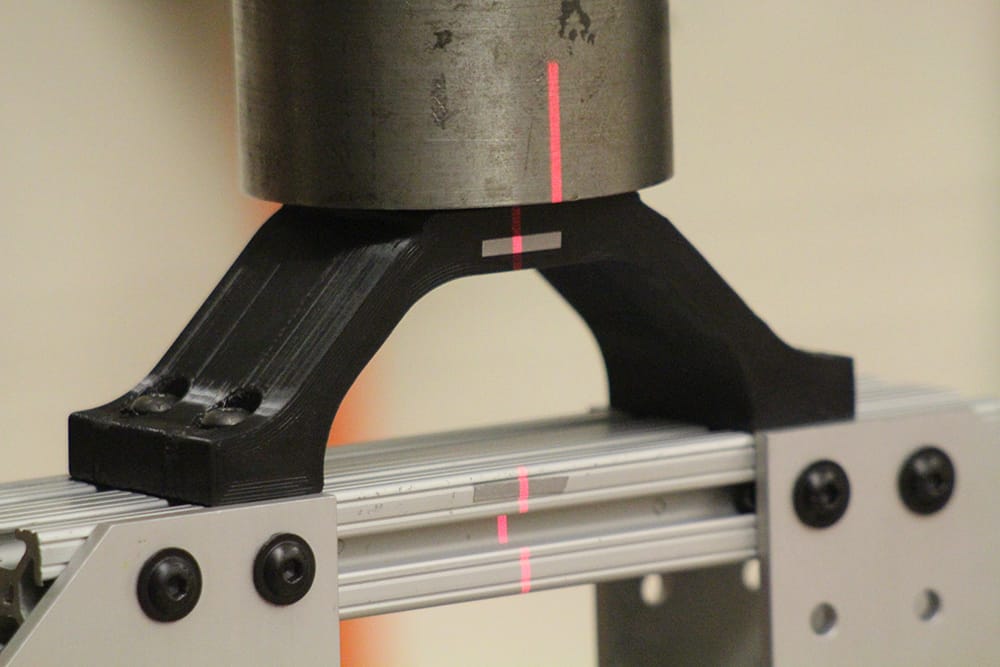

Rise Pavilion is certainly more than impressive. The pavilion weighs in at 1.87 tons, stands more than 11 feet tall, and spans over 1180 square feet. Each of the pavilion’s 5 arcs represents a sector of the competition: heath, transportation, society, education, art and design.

Constructed with over 5,300 poly-blocks that will all be up-cycled into a number of new and decorative pieces. The story behind creation of Pavilion is even more then amazing as the ultimate goal of the project is to make young generations think about recycling and ecological design and to encourage “a shift towards multi-functional and environmentally friendly goods.” Currently, the Rise Pavilion as part of the ongoing Young Creator Cup exhibition in Beijing. As the structure has been constructed with modularity in mind and can be built and rebuilt by simply removing individual blocks, this means when the exhibition wraps up on September 6th, all of the student participants will be allowed to take home a block from the structure to be used as they like.

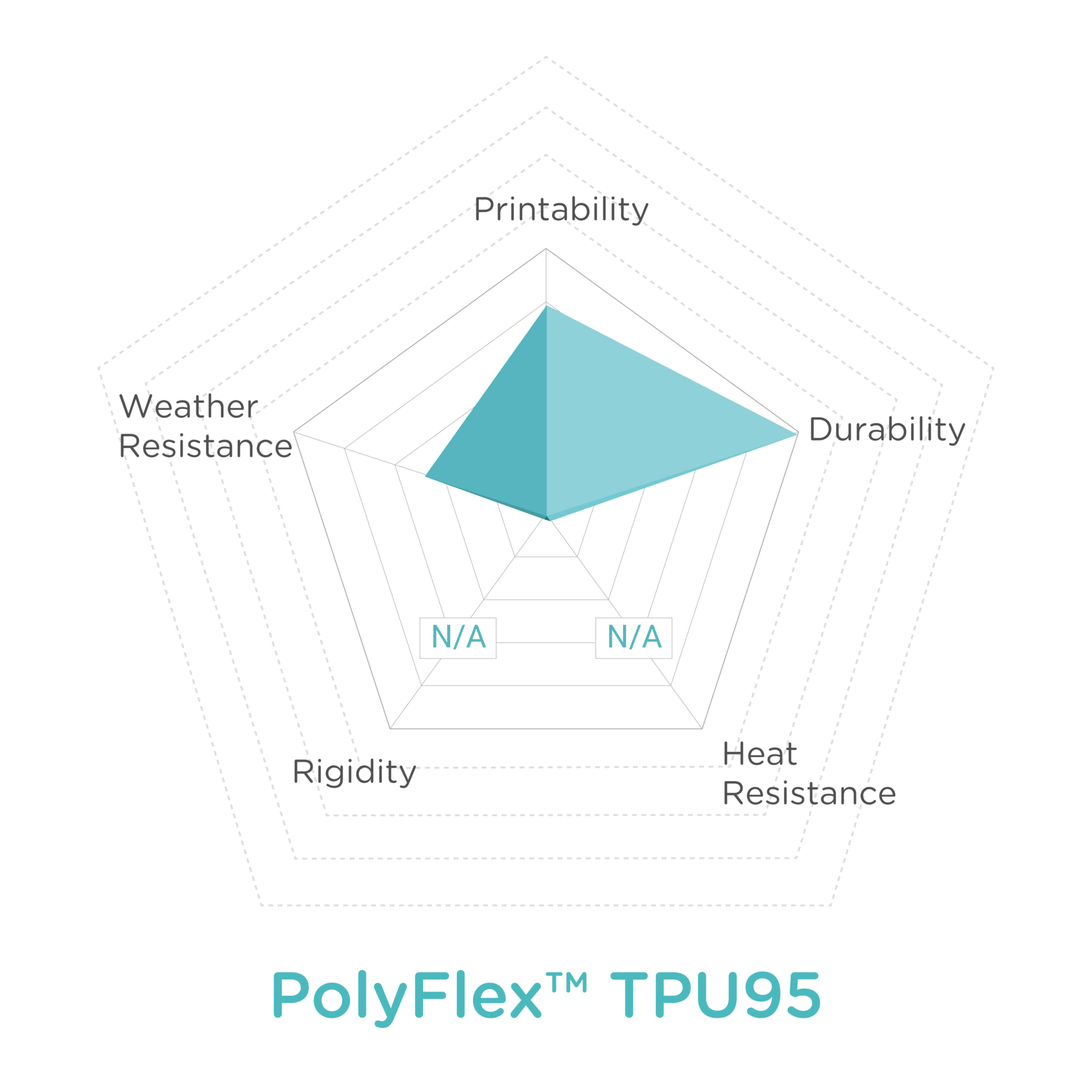

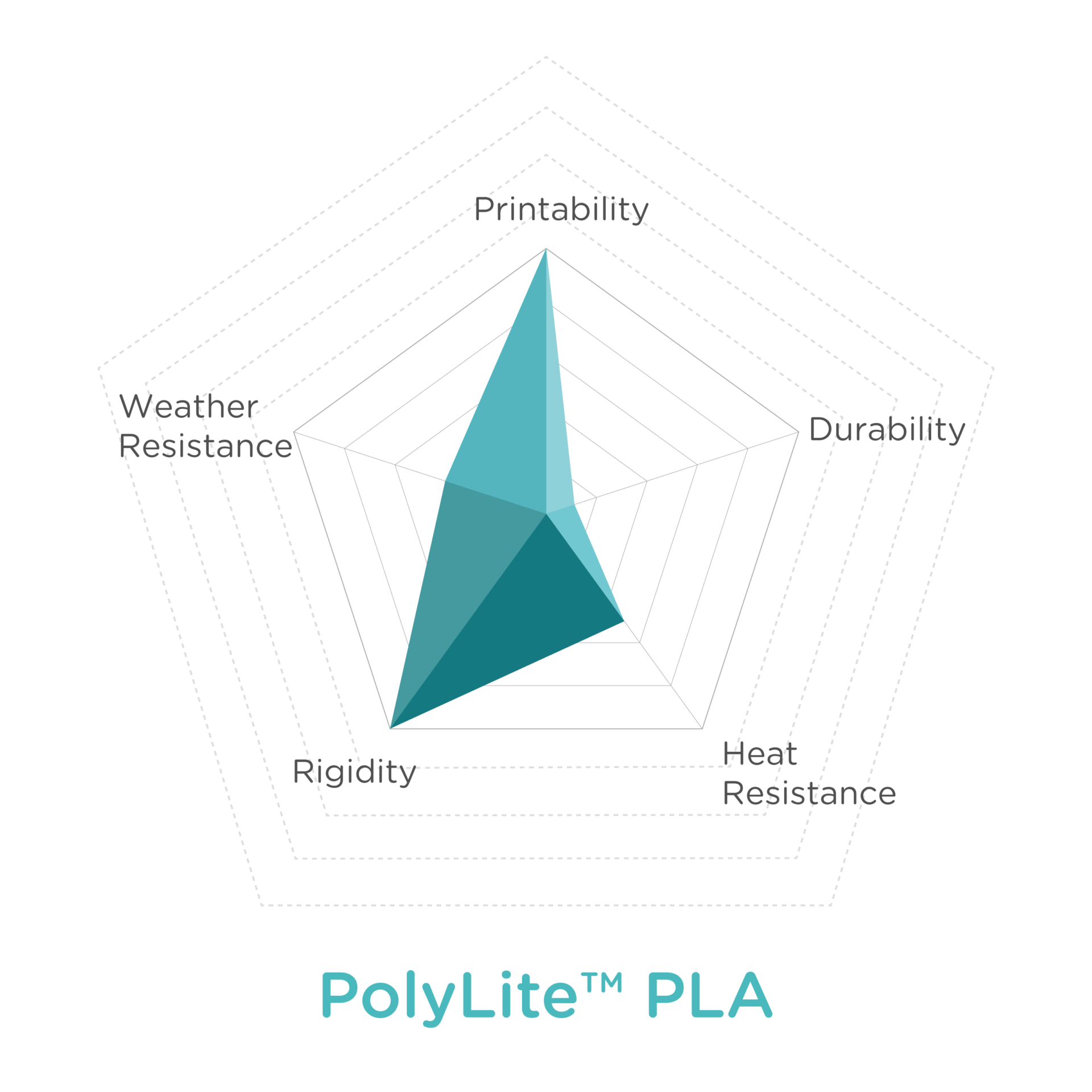

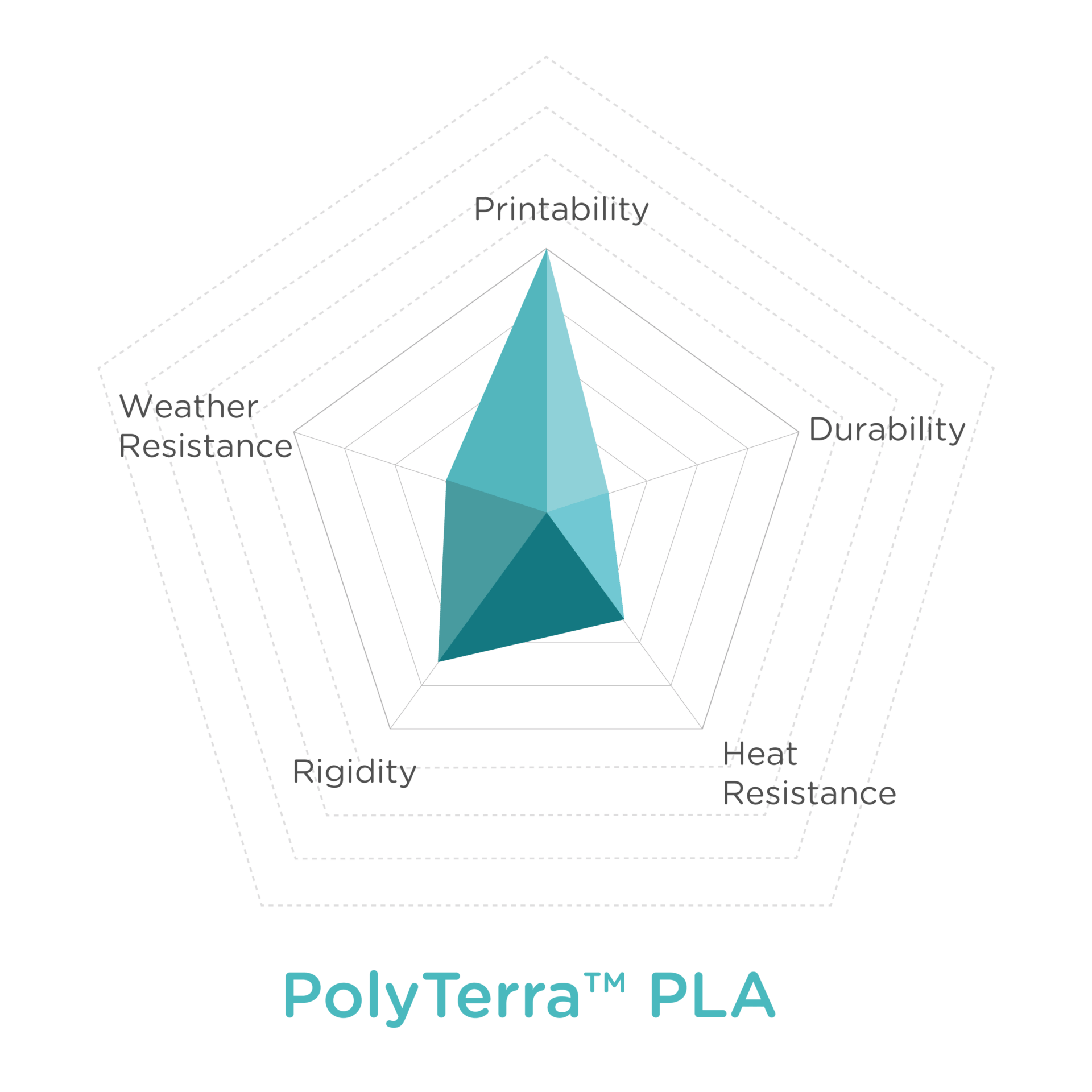

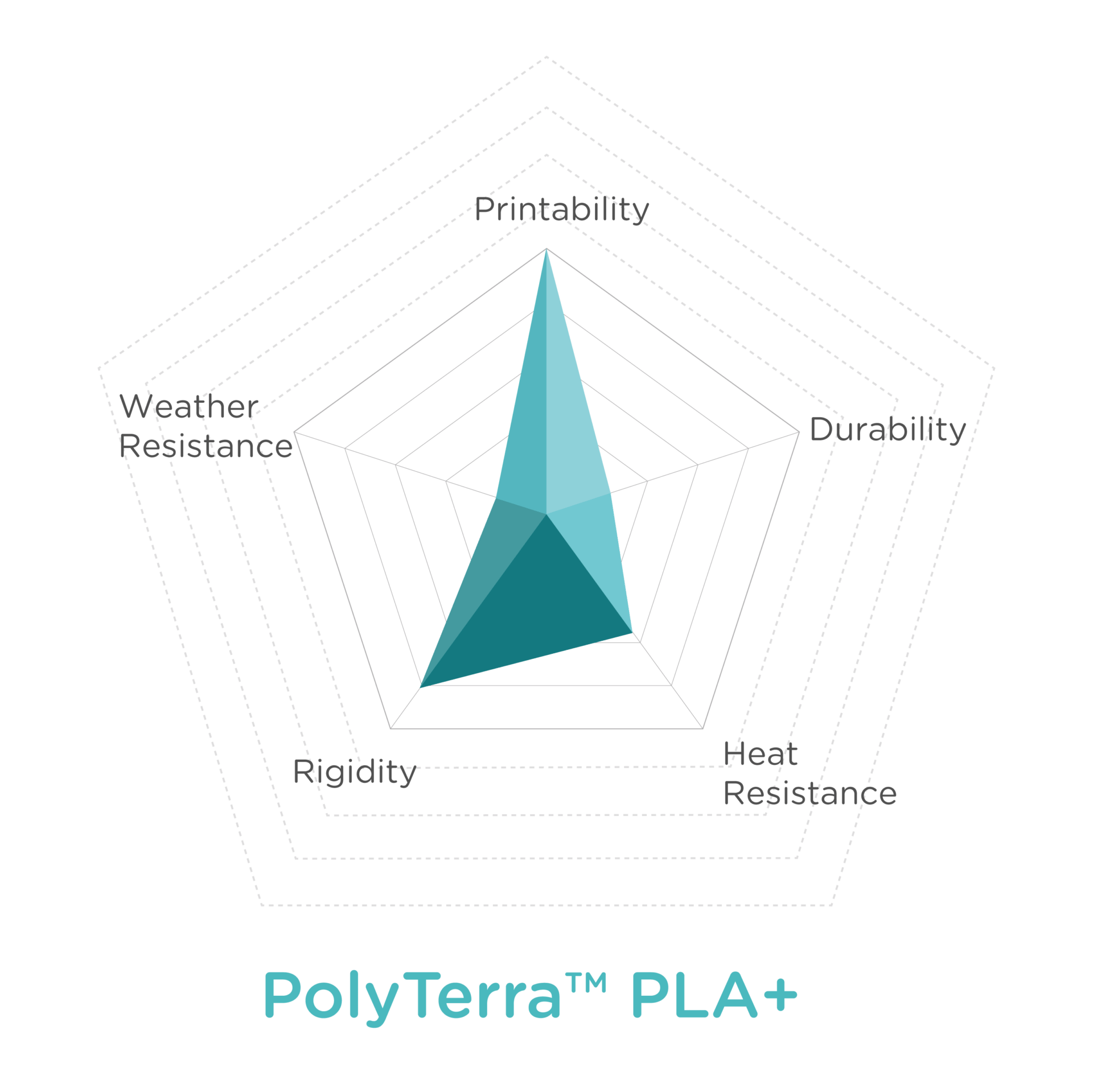

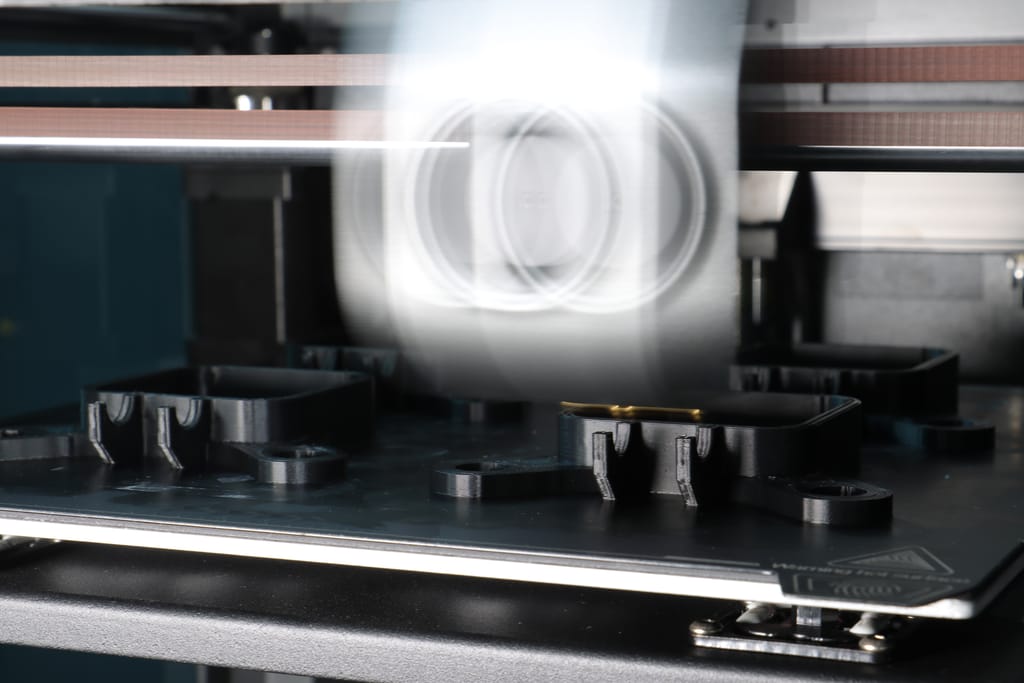

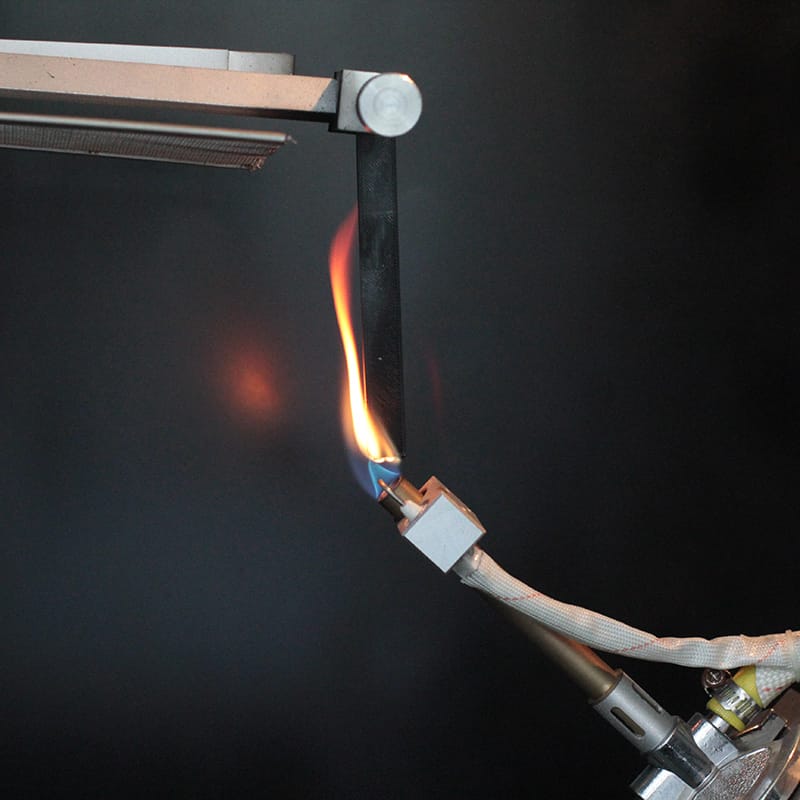

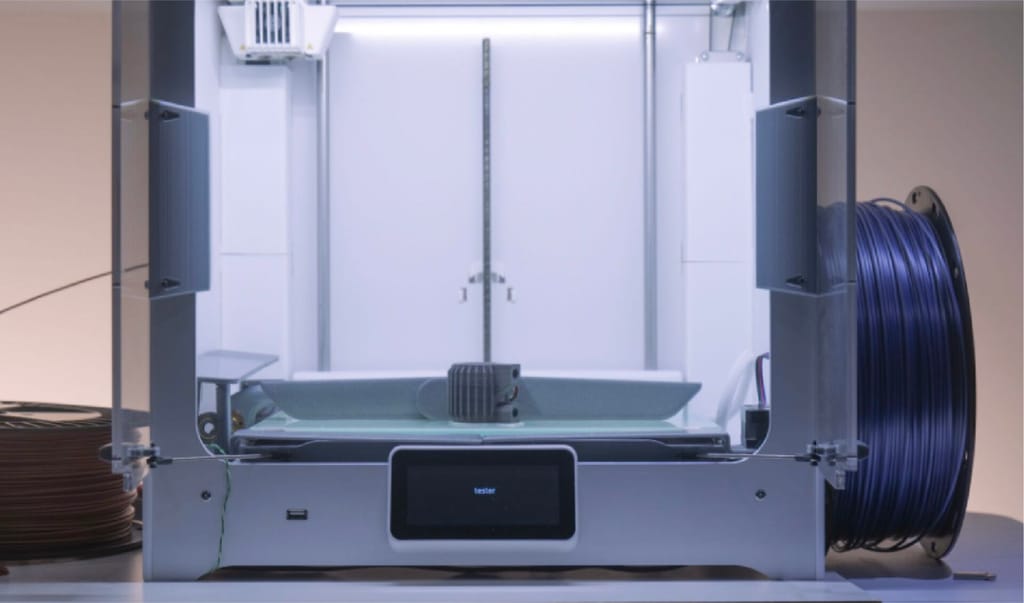

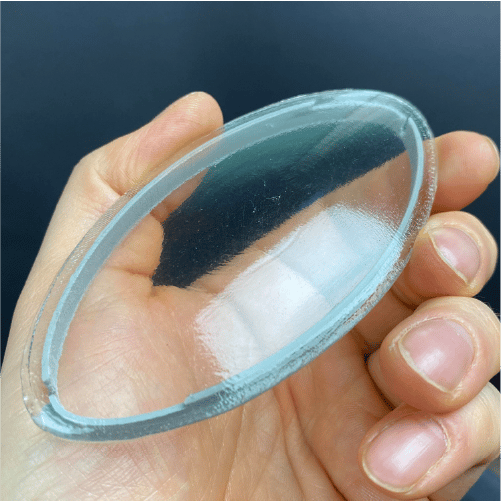

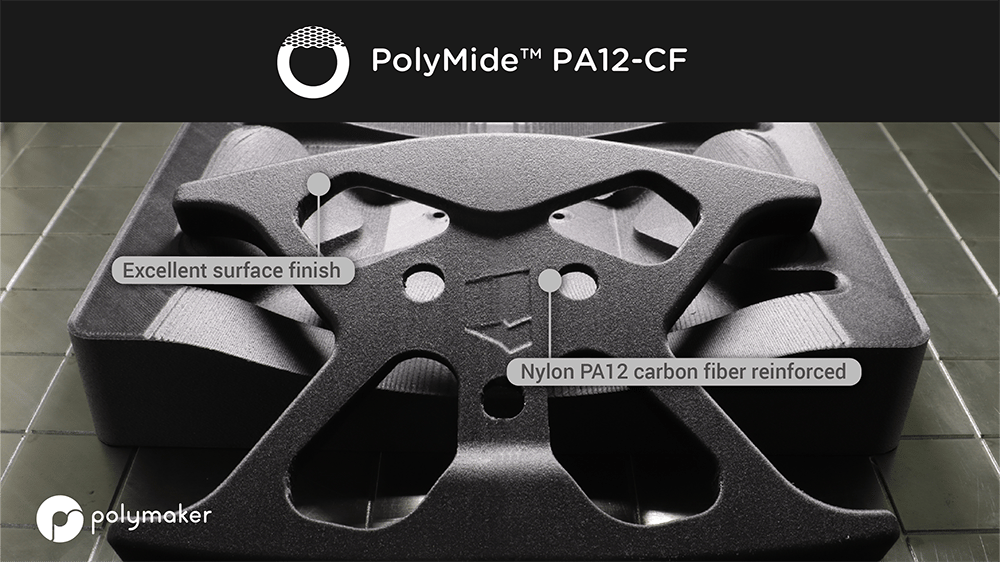

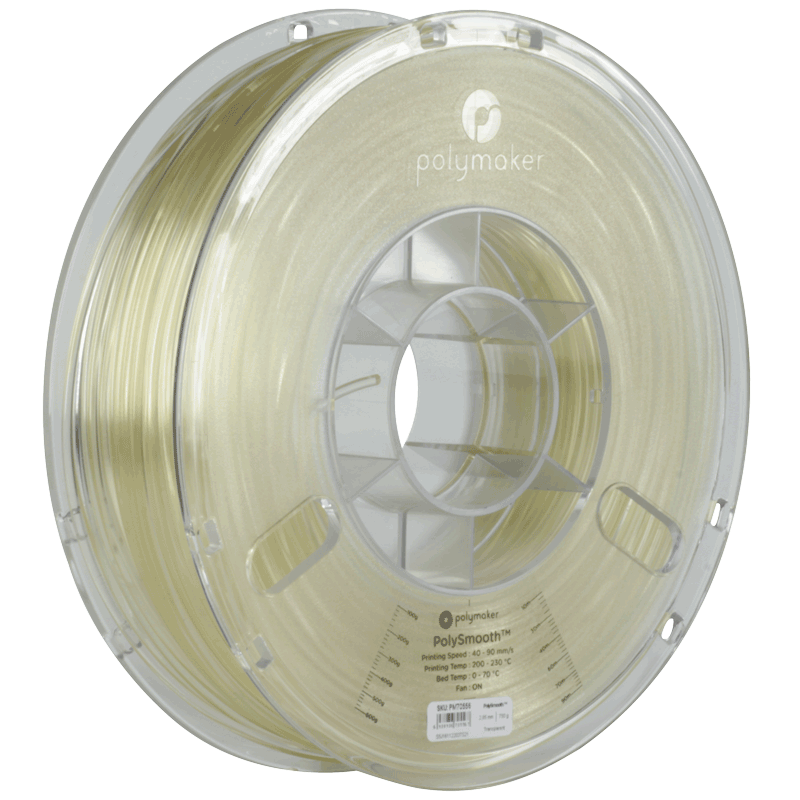

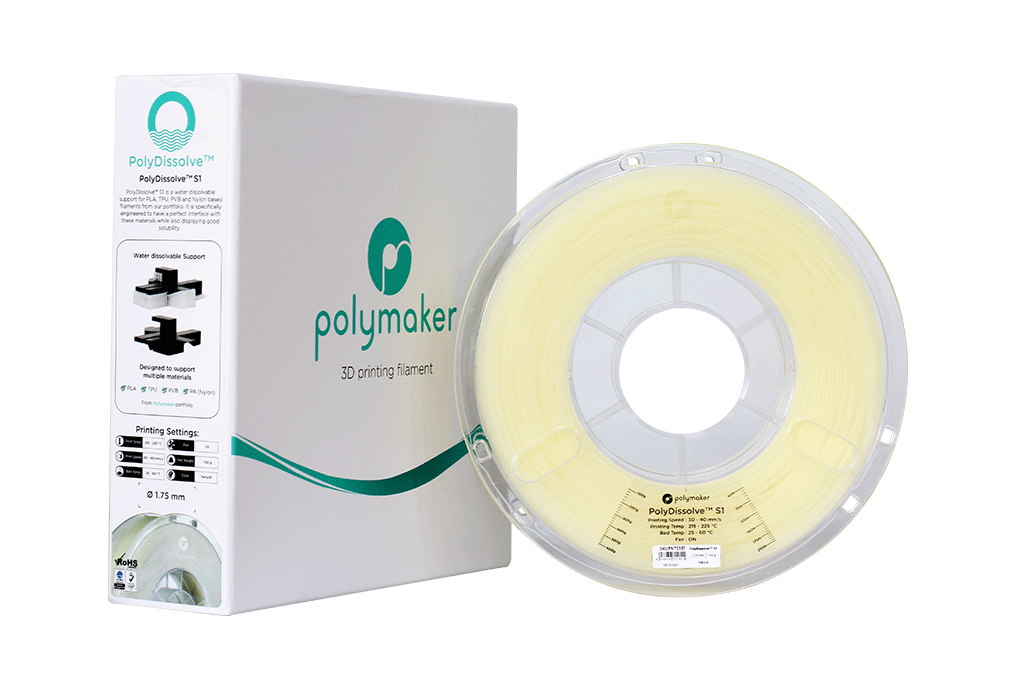

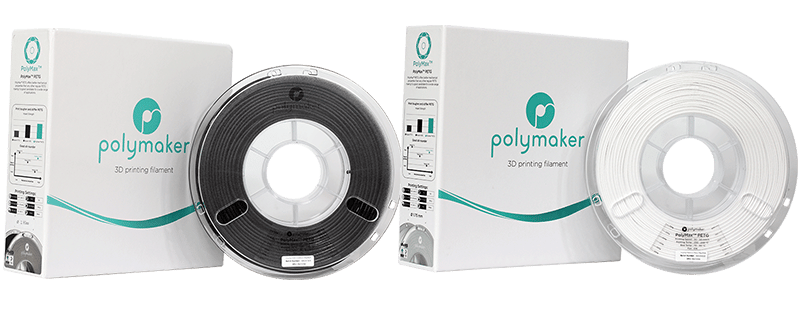

The blocks are designed to be printed without support material and they are made entirely with PolyMaker’s PolyPlus biodegradable filament produced with patented Jam-Free™ technology that ensures consistent extrusion and prevents jams. For the project they employed 70 desktop 3D printers, with DeFacto’s partner UCrobotics, printing out all the parts in 45 days.

Check out our interview with David Doepel, the designer of Rise Pavilion.